Australian Offshore Drilling Fleet Transformed from Out-of-Compliance to World Class

Australian Offshore Drilling Fleet Transformed from Out-of-Compliance to World Class (PDF)

Australian Offshore Drilling Fleet Transformed from Out-of-Compliance to World Class (PDF)

The Situation:

A major international offshore drilling company involved in the completion of exploratory and developmental oil and gas wells was struggling with international regulatory compliance standards. Its offshore drilling equipment includes drillship drilling rigs, semisubmersible drilling rigs and jack-up drilling rigs. As the fleet continued to expand with the construction of three state-of-the-art, dynamically-positioned, dual derrick ultra-deep-water drill ships, it was critical to maintain safety of employees and the environment while protecting financial stability.

The Challenges:

The Offshore Petroleum and Greenhouse Gas Storage (Safety) Regulation of 2009 requires that all offshore oil rigs be regularly assessed by the National Offshore Petroleum Safety and Environmental Management Authority (NOPSEMA).

After a planned inspection by NOPSEMA, the drilling company received an unfavorable rating and was advised to seek a partnership with external experts in asset management to improve safety and reduce operational risks. Such findings justifiably warranted immediate attention by the drilling company for several reasons. Most notably, being labeled as “out of compliance” eventually results in rig shutdown without remediation, which carries a cost of around $.5 million per day. With the drilling company owning three rigs, all deemed non-compliant, the company was forecasted to lose an average of $1.5 million per day. The overarching emphasis in NOPSEMA’s report was the lack of acceptance criteria defined and evaluated within maintenance procedures to determine the performance of Safety Critical Equipment (SCE).

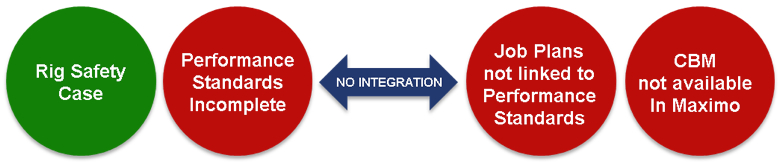

Over half of the performance standards required by NOPSEMA’s validation matrix were either inadequate or not developed. The driller had an existing rig safety case but it needed to complete performance standards with corresponding job plans and to implement a system for Condition-based Monitoring (CBM) to achieve a compliant rating with NOPSEMA.

The driller was tasked with turning around its entire asset management strategy and implementation plan to improve safety for employees, decrease environmental risks and improve overall operational efficiency.

The Approach:

The drilling company and Life Cycle Engineering partnered to develop a set of equipment-related performance standards that contained the function, objective, availability, reliability and maintainability of the safety-critical equipment. The teams worked together to develop performance standards for equipment set forth in NOPSEMA’s validation matrix as well as the equipment categorized by the driller as safety-critical. Performance standards were loaded into the enterprise asset management software, Maximo, and assigned to the corresponding safety-critical element category. Prior to the partnership, the EAM was significantly underutilized.

Safety Critical Element (SCE) assets were cross-referenced to Major Accident Event (MAE) controls as identified in the individual rig safety case reports and newly established preventive maintenance job plans for each asset or group of similar assets. The job plans developed include measurable parameters in the form of clearly defined acceptance criteria in which key measurements and checks are regularly evaluated and compared for identification of trends and rapid implementation of corrective action.

Performance Standards (PS) were prepared to summarize the parameters under performance criteria, provide general background information on design requirements for the assets covered by each PS and to provide a cross-reference to the supporting job plans. Job plans were created for each safety-critical piece of equipment to provide traceability from job to MAE controls.

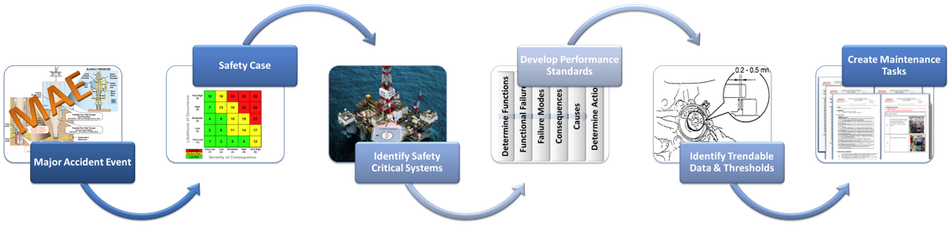

The teams worked together to create Critical Asset Performance Standards through a comprehensive approach that factors in the International Standard for Asset Management taxonomy and guidelines as well as the following elements.

- Major Accident Events (MAEs)

- Safety Case

- Identify Safety Critical Elements (SCEs)

- Develop Performance Standards (PS)

- Identify Trendable Data and Thresholds

- Create Job Plans and Maintenance Tasks for SCEs and non-SCEs

The process flow below was followed to create an effective asset management and maintenance plan.

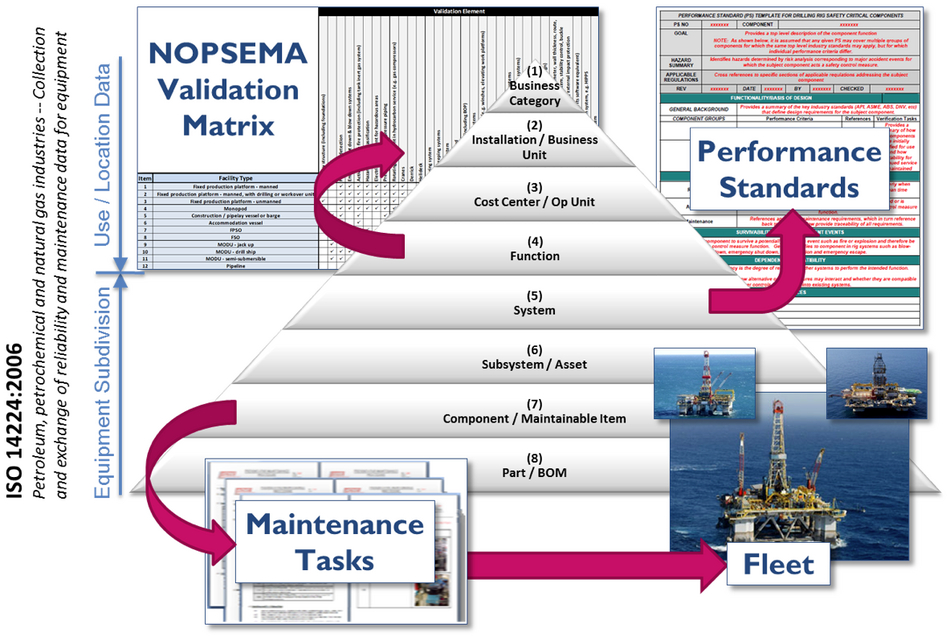

The International Standard for Asset Management’s taxonomy and guidelines (ISO 14224), along with the NOPSEMA Validation Matrix and LCE Performance Standards development, all factored into the construction of the drilling company’s new asset management plan.

Critical Asset Performance Standards were developed for each piece of the equipment related to the validation elements in the NOPSEMA Validation Matrix (N-04200-FM325, Object ID A25235) and the assets not contained within the matrix deemed critical by the driller. The performance standards were compiled in Maximo-compatible formats, assigned unique identifiers and referenced to the corresponding validation element or safety-critical element categories to maintain traceability to the safety case.

The equipment maintenance plans and preventive maintenance tasks which contain acceptance criteria and trendable measures where appropriate were also provided for migration into Maximo to leverage the Condition-based Monitoring application to define continuous, gauge and characteristic meter points. By utilizing both a common and rig-specific set of job plans, these job maintenance tasks have been successfully rolled out to the entire fleet of semisubmersible drill rigs off the coast of Australia.

The Results:

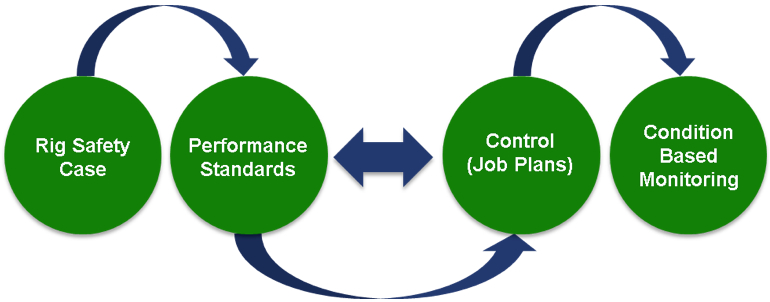

LCE and the drilling company were able to establish a comprehensive maintenance management system based on best practices that meet the regulatory scrutiny of NOPSEMA and the Bureau of Safety and Environmental Enforcement (BSEE). The management system now provides transparency of asset-related risks and control measures that mitigate or eliminate risks to ensure corporate stewardship of the environment, along with health and safety of its personnel and the public.

The teams worked closely together to establish a comprehensive maintenance system capable of implementation across the entire fleet with a strategy for expansion to additional high-specification rigs currently under construction, positioning the drilling company for even greater success in the future. With a $2.3 billion per year contracting rate per rig, a three percent increase in uptime equates to an additional $69 million in revenue per year. Needless to say, the improvements made to the asset management system and overall maintenance strategies yielded substantial results.

As a result of the partnership, in less than a year, the driller’s Australian fleet maintenance system was transformed from out-of-compliance to “world class,” according to NOPSEMA.

© 2014 Life Cycle Engineering, Inc.

For More Information

843.744.7110 | info@LCE.com