Examining, Analyzing and Cultivating the Skills for Tomorrow

As appeared in Reliable Plant Mail e-newsletter

Managing a business is a creative balance of supply and demand. Your business is focused on bringing in new customers, retaining existing customers and optimizing plant performance to match the growing demand. This is the nature of competitive business and what drives most business leaders toward excellence. However, over the past 20 years, following the post World War II “Baby Boomer” era, most companies have neglected to forecast the demand on knowledge, skill and raw intellectual ability required to sustain their business’ growth.

On average, 50 percent of today’s manufacturing workforce is at retirement age, meaning half of our intellectual capacity could walk out the door tomorrow, leaving our businesses at risk. If we look specifically at engineering disciplines, which most of our companies rely on day-to-day to manage plant operations, maintenance and reliability functions, most of our knowledge is based on outdated technologies. Research provided by one engineering trade magazine forecasts a 30 percent increase in automation and instrument controls – this correlates to nearly 70 percent of plant operations being automated in the year 2011 – yet we continue to defer the necessary training to support automation technologies. Even those organizations that have become aggressive in training maintenance and engineering personnel are doing so at a rate which many might consider reactive and insufficient to meet automation demand by 2011.

Throughout the world, engineers are in demand. Most heavy manufacturing plants struggle to compensate for the erosion of knowledge due to retirees within the workforce. Many have focused narrowly on improving the integrity of document management systems and data repositories in an effort to retain intellectual property. Few have started looking into the future in an effort to predict the skills necessary to run their facilities. My question is this, why invest precious training resources in skills that will be obsolete in the next three years? For most it’s a matter of survival, a futile attempt at preserving knowledge within the organization.

Predicting Training Needs for the Future

Good training programs focus on a systematic approach which begins by analyzing job responsibilities and skill requirements to meet performance expectations within each job. This is known as a Job Task Analysis, or JTA. This same principle can be applied toward future expectations.

As business leaders, we’ve been trained to look at both short-term and long-term performance goals for our organizations. In doing so, we realize that current productivity levels do not match tomorrow’s demand. As a result, many businesses are engaged in lean implementations which are geared toward applying techniques which will drive out variation, waste and other sources of inefficiencies that may result in lost capacity or increased cost. With that said these same organizations are taking time and investing in the necessary training of leadership and the workforce in order to implement lean tools and methodologies. But, what about our jobs in the lean environment? What new skills will be required to run a just-in-time operation? What new skill sets will be required within the maintenance and engineering functions to manage assets more efficiently, supporting the principles of lean? To answer these questions, we have to take JTA to a whole new level by examining and analyzing the responsibilities or changes in responsibility as a result of new business processes and practices.

Let’s just suppose, for example, that your organization is beginning its lean journey and the initial two-year goal is to transition maintenance from reactive to proactive in order to more effectively manage plant assets and increase uptime availability for operations. In this type of improvement initiative, your organization would begin by defining proactive maintenance processes, such as work planning or work scheduling, and compare them to the current reactive processes. The delta between current and proactive is not only the waste that must be driven out; it is also the gap in responsibilities.

Let me expand this idea a little. In the reactive organization, operational leaders are applying pressure to maintenance and engineering to resolve equipment downtime issues in order to meet customer demand. In turn, maintenance is forced to defer the much needed preventive maintenance routines so that they may give priority to more emergent or urgent work. If 40 percent to 60 percent of the work falls into the “emergent” category, then what skills are predominant and preferred within this reactive maintenance organization? Troubleshooting expertise, detailed yet narrow equipment knowledge, inventiveness, “at all costs” attitude, and technical repair vs. prevention are just a few which begin to describe the traditional “firefighter”.

But what about the goal of proactive maintenance? If maintenance leaders invest training resources in firefighting skills in an effort to preserve the reactive knowledge base that is in predominant demand, then how will your maintenance organization ever reach proaction? Who will learn the planning skills? Who will have the knowledge of predictive maintenance technologies? This is the problem with industrial education as I’ve seen throughout the world, in many different industries. Ten years ago, apprenticeship programs were deemed superfluous, a nice-to-have expense that most financial controllers chose to live without. Within the past five years, many companies, especially heavy industry, have regained their training focus as a result of union pressures and the need to improve safety and environmental control. However, the focus 90 percent of the time is on “skills retention”, rather than skills development, due to the average age of the workforce and current performance objectives.

Linking Skills to the Business Process

The skills and knowledge that your organization holds in highest regards are those which directly impact the performance of business processes.

“We need a metamorphosis of education – from the cocoon a butterfly should emerge. Improvement does not give us a butterfly only a faster caterpillar.”

- Learning to Learn

To improve your business, your organization must re-engineer the fundamental business processes, however, to improve your processes you must transform people through education. People are the variable in every process and practice within your business. To limit variation in performance, business leaders need to recognize the need for new skills and levels of knowledge in order to gain additional growth through process improvement. Business Process Re-engineering (BPR), a term developed by the late Dr. Michael Hammer, is designed to illustrate the routine steps and tasks necessary to perform a specific function of business, in a sequence that is most efficient. Additionally, through developments in performance management, BPR provides each and every organization with the ability to link functional roles to each step, thus aligning responsibilities with the business process. The tool used for this purpose is called a RASI, or RACI in some improvement circles. RASI stands for Responsible, Accountable, Support and Informed.

The “R” in RASI is the role within your organization that is selected to perform the step and, therefore, must have the skills necessary to do so effectively. The age of job descriptions has past, and the new era of performance management is contingent upon role responsibilities and expectations, commonly known as RRE’s. Defining the “R” for each functional role is the first step in job task analysis for the future.

As you progress, through the improvement initiative, RASIs should be compiled to form role expectations, beginning with skills and knowledge. For example, typically reliability engineers are tasked with the facilitation of criticality analysis within the process of developing preventive maintenance programs. If the “R” is assigned to reliability engineers, then those individuals must be trained in criticality analysis, as well as, the fundamentals of Reliability-Centered Maintenance (RCM) in order to guide a cross-functional group through functional failure identification and evaluation. Another predominant example, keeping with the theme of proactive maintenance, is the assignment of R’s to the planner role within the work control process during those steps that are focused on preparing job plans for craftsmen. In order for planners to be effective in job planning, they must have sufficient knowledge of the computerized maintenance management system, be competent in the practices of analytical estimating and fully understand the principles of critical path analysis, in addition to having an innate and broad knowledge of plant equipment and foundational maintenance practices.

Business Case for Tomorrow’s Education, Today

As with any improvement process, educational improvement begins with the end in mind. As your organization defines the performance objectives relative to future business demand, you must ascertain the value of achieving each objective and the correlating cost of training and education. In this context, the business case for training is based on the benefit of each objective. Simply said, if your company is focused on transitioning from reactive maintenance to proactive maintenance, then the return on the training investment is lower maintenance costs. For those readers who might see training as an indirect link to the forecasted benefit of cost reduction, then allow me to paint a more direct picture for your business case.

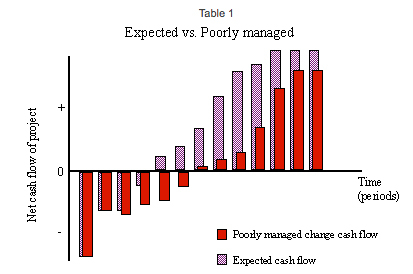

Research through benchmarking organizational change has provided us with a much stronger understanding of how a lack of skills and knowledge impacts the business’ bottom line during improvement initiatives such as lean. The data speaks to the fact that benefits were delayed in 100 percent of those companies surveyed who did not have an educational component within their change management strategy. In comparison, those companies who invested in knowledge and skill enhancement increased their rate of return by nearly 17 percent on average – referring to the time interval from investment to savings. The Change Management Learning Center sponsored by Prosci illustrates the cash flow impact of a poorly managed change strategy in Table 1.

Education is a key component of the change process and directly impacts your organization’s ability to adopt the new business processes, fully utilize solutions designed to achieve future objectives and develop the required level of proficiency to empower employees with the skills necessary for continuous improvement. If the benefits of your solution are based on raising the knowledge base then your organization must invest early in education or returns will be sub-optimized.

Knowledge is power only if it aligns with organizational practices. Investing today in education ensures sustainable growth tomorrow in an increasingly competitive business environment. Don’t allow your skills to become reactive and obsolete. Identify those skills that will be required in the future and begin your educational metamorphosis.

© Life Cycle Engineering, Inc.

For More Information

843.744.7110 | info@LCE.com