Failure Analysis Project Examples

Failure analysis tasks have been performed on numerous components from diesel engines, gas turbines, piping systems, gears, fans, bearings, steam systems, and miscellaneous ship systems. Examples include:

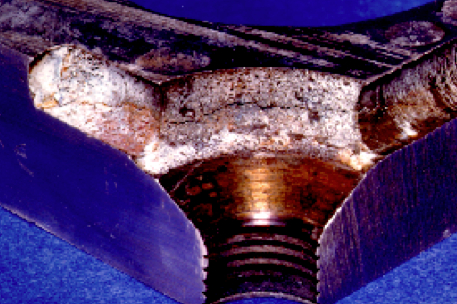

Cracked Diesel Engine Cylinder Heads

Evaluated strength vs. structure for numerous heads and determined fracture occurred in heads with brittle graphite structure at critical location. Recommended processing and testing to ensure required structures and properties are consistently achieved.

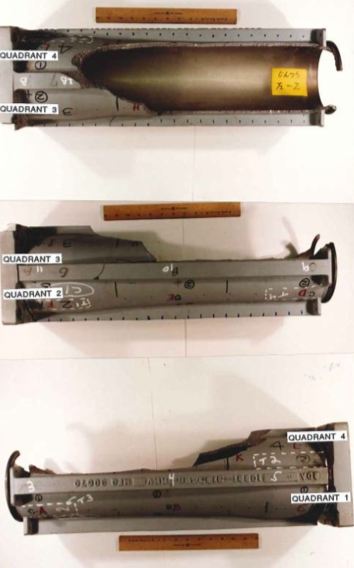

Fractured Cast Aluminum Decoy Launch Tube

Determined fracture resulted from low ductility produced by elongated silicon particles and needle-like iron phase. Recommended fleet inspection requirements and changes in casting process.

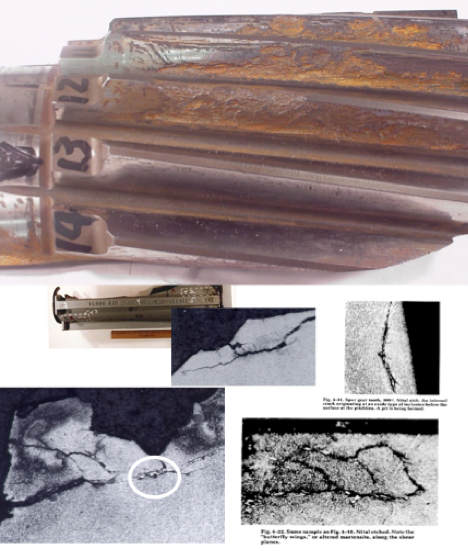

Fractured Fan Drive Gear

Clear metallurgical evidence showed root cause as overload with no evidence of damage resulting from lubrication failure as claimed by gear manufacturer. Gear manufacturer installed higher rated gears.

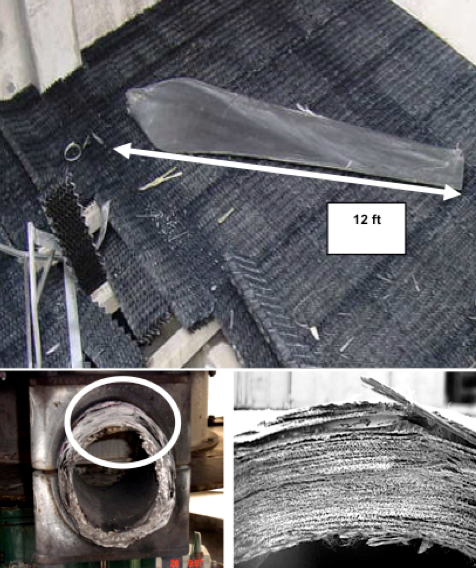

Broken Composite Fan Blade

Defective construction allowed fatigue crack to initiate on blade tension side. Blade manufacturer was unaware of QA problems, which were corrected. New blades were provided to the customer.

For More Information

843.744.7110 | info@LCE.com