Hillbilly RCM

As appeared on www.PlantServices.com

I have always believed that Reliability Centered Maintenance (RCM) is a very logical and effective way to approach the development and continuous analysis and effectiveness of reliability programs. I also am aware of the tremendous amount of time and training, which translates to costs, it requires conducting a full RCM analysis, especially if you require each of the participants be trained and certified in RCM techniques. If the cost of loss or the consequences of failure warrants an exhaustive analysis, then by all means, get on with the program. If not, I would like to introduce you to a very simple approach to RCM that can deliver much of the value of the more rigorous approach by taking a more practical approach.

“Hillbilly RCM” is a concept I first heard from Ron Moore during one of his “Reliability Leadership” workshops. Ron’s intentions were to have the workshop participants embrace the principles of RCM and apply them on a daily basis in a very practical way as opposed to only applying these principles on a formal basis. When a piece of equipment does not perform to specification or when catastrophic failure occurs, the basic “Hillbilly RCM” questions that must be asked and ultimately answered to start the process of creating a root cause analysis culture are:

- What is it supposed to do?

- What is it not doing?

- How much pain is it causing you?

- What are you going to do about it?

If these very simple questions were considered and answered each time a failure occurred, many of the failures would be solved and our reliability program and bottom line results would be vastly improved.

Let’s examine this methodology:

What is it supposed to do?

This question is simply having people on the floor determine the primary function the equipment is designed to perform to support the process. This question is fundamental to the RCM process -- it helps us understand the relative importance or criticality of the specific piece of equipment in the process.

What is it not doing?

Understanding the function that is no longer being performed helps us understand the possible causes for the failure and zeros in on the specific failure that caused the breakdown. The risk in this approach is that root cause determination may result in identifying a symptom and not the ultimate root cause.

How much pain is it causing you?

The total financial impact of the failure is generally much greater than most people think. Most trades people consider the cost of the parts and labor of the work associated with the repair. The rest of the story can be staggering to operations in loss of production. Depending on the specific process, loss of production revenues can be from 1.5 to 10 times the cost of the work. This analysis, even at a gross level, gives us the basis for how much we can justify mitigating the cause of the failure.

What are you going to do about it?

Other than making the repair, we need to consider what action we need to take to prevent this failure from occurring again. Simply stated there are three broad categories of failure to consider:

- The equipment was not operated correctly.

- The equipment was not maintained properly.

- The equipment was not capable by design.

Be careful in making this determination, too many times the search for the culprit clouds an objective analysis.

I don’t mean to suggest this as the only approach to achieve improved reliability in your plant or facility, or as a replacement for sound work processes and technology, but it will go a long way to change the way you think and behave, which is really what you want to accomplish if you are operating in a reactive or high cost environment.

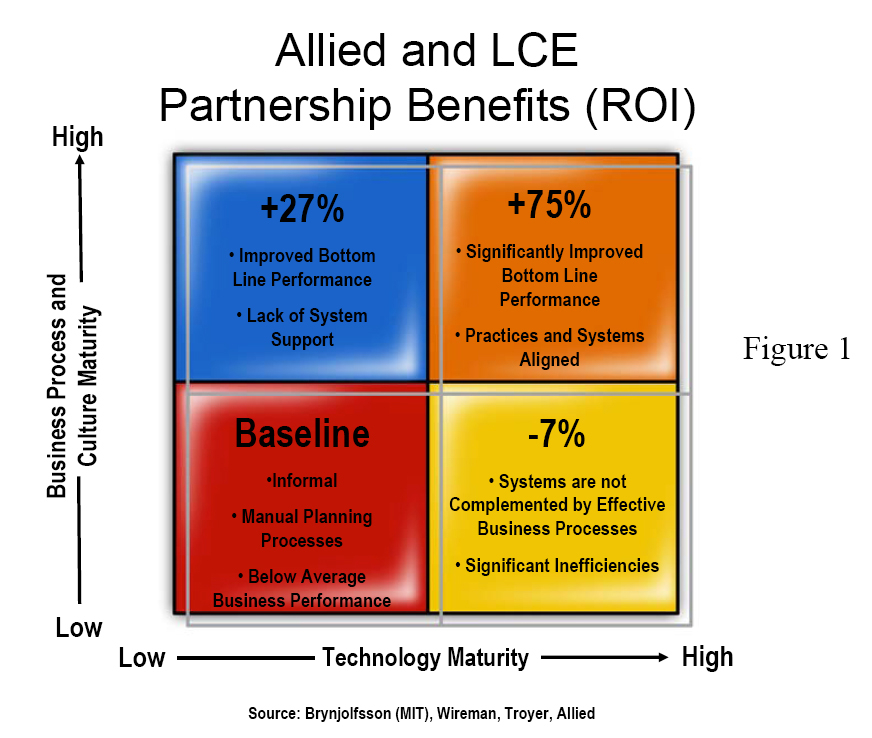

A new or different way of thinking and behaving, or a culture change, is exactly what you need to accomplish. Tools, technology and well defined work processes are certainly important, but when technology alone is applied in a reactive environment very little is accomplished. In fact, a study conducted by MIT suggests that technology maturity without culture and business process maturity yields a negative return. Only when we combine the two, technology and culture/business process, do we see significant positive returns. (See figure 1)

Unfortunately, the “Hillbilly RCM” method does not address some of the more fundamental issues of true RCM analysis such as Failure Modes and Effects Analysis (FMEA). This type of analysis is the most effective way to determine the optimum maintenance strategy including preventive and condition monitoring routines to generate the data required to effectively prevent or predict failure. Many attempts to shortcut the FMEA process developed over the years have focused on achieving the most value of the analysis with the least effort and just as important to most plants and facilities the least cost. Traditional FMEA methodology results in developing from scratch an optimized failure mitigation strategy by considering all possible failure modes. It takes into account the effect these failure modes have on equipment performance, all possible failure mitigation strategies, and the financial risk analysis associated with performing the mitigation compared to the cost of failure.

Another methodology we have used successfully is Simplified Failure Modes and Effects Analysis (SFMEA). This methodology examines existing preventive and condition monitoring routines to determine if they are actually in place to effectively prevent or identify a failure mode. To develop an appropriate maintenance strategy for your equipment rigorous, analysis is required. If a preventive or condition monitoring routine is not directly aimed at eliminating or identifying a specific failure mode, the effort and cost of performing the tasks are a total waste of time, money and effort.

In our experience, looking at thousands of reliability programs in multiple industries, many of these routines are what I refer to as “feel good” routines. They are simply replacement or rebuilt routines that are recommended by vendors that are in the business to sell parts or benefit from failures. These activities are fairly worthless or create more problems than they solve, due to the fact that only 10-12% of failure is age related. My friends from Allied Reliability, Inc shared some interesting statistics resulting from their analysis databases of hundreds of reliability programs that rely heavily on traditional time-based preventive maintenance routines. They discovered:

- Approximately 30% of PM activities could be eliminated with virtually no impact on equipment reliability.

- Another 30% could be replaced with condition monitoring.

- The next 30% are useful, but could be drastically improved utilizing the SFMEA process.

- The remaining 10% can remain in tact as they are written.

If we could capture even a small portion of the total dollars wasted in this country on ineffective preventive maintenance programs, the national debt could be eliminated in short order.

By embracing the principles of RCM starting with 4 simple Hillbilly questions, applying the answers to the questions on a daily basis in a very practical way, then you will begin reap the rewards of reduced failures and therefore costs and increase your facility’s reliability.

© Life Cycle Engineering, Inc.

For More Information

843.744.7110 | info@LCE.com