How to Align an Industry 4.0 Strategy with your Asset Management Strategy

By Rick Wheeler, Vice President, Professional Services, Life Cycle Engineering

Much has been written about Industry 4.0 and there is little doubt that companies will increasingly leverage digital technologies to improve their bottom line. But what specifically does Industry 4.0 mean to your organization? What is the right level of effort for your enterprise to invest in digital transformation? Which new technologies should your organization incorporate into your business?

If money were not an issue

In a world without constraints, your organization might build a digital twin of your complete operation. If you had very high levels of asset management maturity, you would leverage easily accessible data to self-monitor assets, automate best course of action, build resiliency, and optimize performance. Your COO might link your digital twin to a vast database of performance metrics, system tolerances, and intuitive alert mechanisms designed to optimize production. Your CIO might develop a strategy to align your firm’s technology architecture with machine to machine (M2M) communications and condition assessment tools that are powered by artificial intelligence.

How do you determine what Industry 4.0 strategy is right for you?

It’s important to ask these questions:

- Is that what your firm needs right now?

- What specific problems are you trying to solve?

- Does your team have the necessary skills to pull it off?

- Are you currently taking advantage of the data that is currently available to make improvements?

- Do you have the organizational competencies to take advantage of these capabilities and find a positive ROI on the substantial investment of time and resources?

- Can your business tolerate the disruption while you prioritize these changes?

There is no cookie-cutter answer to how to approach Industry 4.0, IIoT, or digital transformation. Firms need to prioritize building the capabilities and competencies that provide near-term tactical benefits while developing long-term initiatives and principles that align with their strategic objectives. Organizations need to roll out a performance improvement strategy that works for them, which their workforce will adopt, and then determine how using data will expedite, sustain, and continuously improve the business transformation goals and objectives.

Industry 4.0 for asset-intensive organizations

The Industry 4.0 concept has been around since 2011 and one could argue that the concepts were in place well before it earned the name. And while there are companies today that have deployed some or even significant levels of digital technology, there are very few that have effectively leveraged it. With all of the potential benefits of Industry 4.0, why have so few companies effectively deployed an Industry 4.0 strategy, or for those companies on the 4.0 journey where is the return on investment?

LCE’s experience helping asset-intensive organizations optimize operations proves that many organizations are unsuccessful in deploying effective Industry 4.0 strategies because they lack the ability and insight to right-size their specific digital transformation and align it to a comprehensive asset management strategy. These organizations often do not have sufficient foundational asset management competencies to take advantage of technologies that (theoretically) will improve organizational performance. To gain a positive ROI on Industry 4.0 and IIoT initiatives, firms need to master fundamentals in order to realize the potential benefits of cutting edge technical tools.

For example, we have worked with many clients who are unable to track their assets’ cost, work order history, or uptime performance in their eAM system or enterprise asset registry. These organizations often lack clear asset hierarchies, criticality scoring, written maintenance strategies, bills of material, or standardized maintenance processes that are required before any digital strategy can be effectively deployed. Their inventory systems often do not integrate with their asset management systems. They have little insight into asset criticality, rotating items, spare parts inventory management, planning and scheduling of maintenance work, and work management best practices, all of which are required to get the benefits on any digital strategy investments.

For these firms, an expensive machine learning system that constantly scans production data to automate intricate adjustments to operating parameters is, at best, going to fall short of expected ROI goals. At worst, it will create customized processes that cannot be reproduced in other parts of the organization and which require human intervention that is so excessive that it wipes out any productivity gains.

Organizations that are a bit higher on the Asset Management Maturity Curve might still have significant barriers to adoption of some Industry 4.0 technologies. The organization might have maintenance history on assets. They may have built process data historians that capture details such as pH, pressure, temperature, flow rates. This is valuable data which is often included when analyzing root cause failure after an event has occurred. Yet without a comprehensive reliability program, those firms struggle to understand the nuances of cause and effect and how to engineer repetitive failures out of the system. These firms become experts at predicting the same failures over and over again.

So where does your organization need to start? Align your Industry 4.0/digital strategy to your asset management program

A leader in asset management since 1976, when LCE began developing reliability programs for the U.S. Naval nuclear submarine fleet, we have developed asset management, maintenance, and reliability best practices to cover the entire life cycle of an organization’s physical assets.

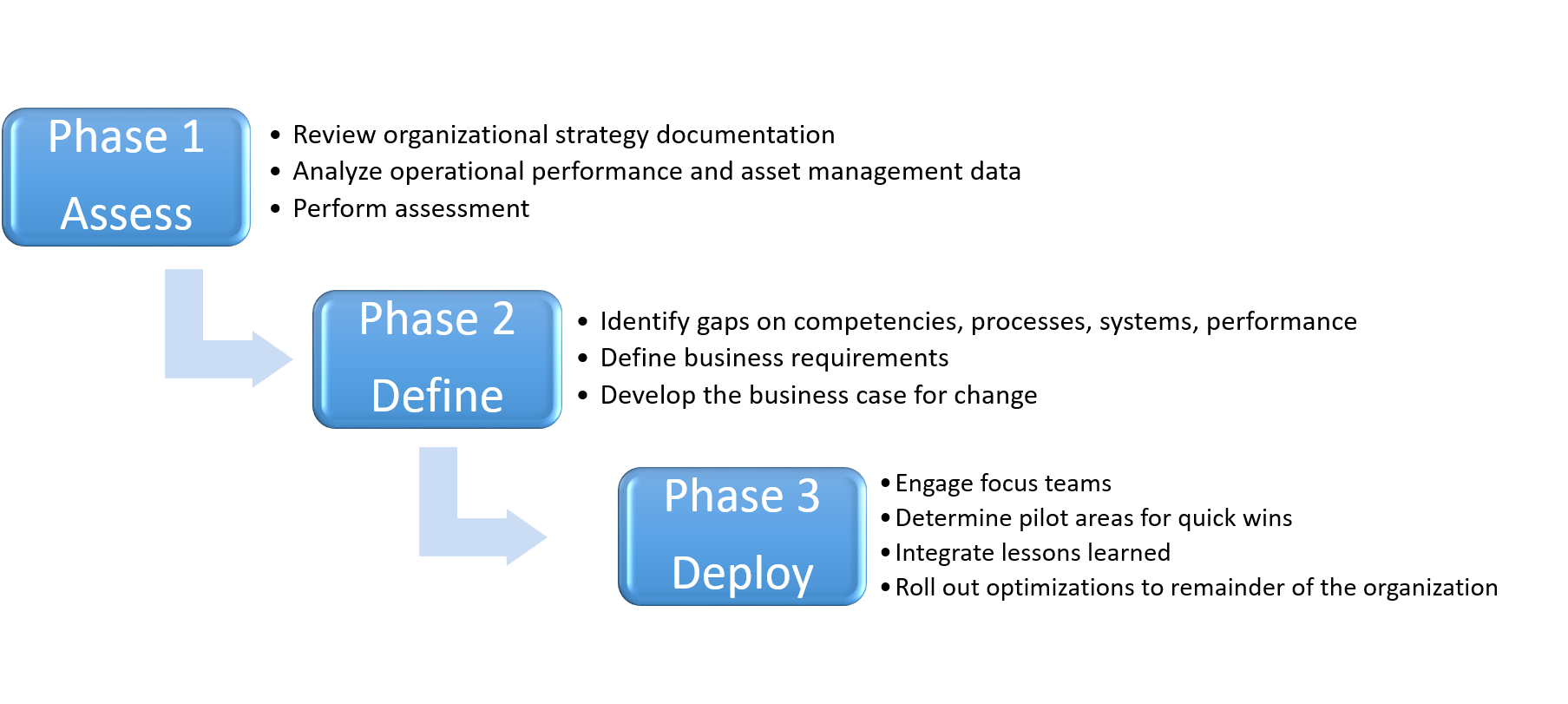

Our experience is reflected in this practical approach to aligning an asset management foundation with an Industry 4.0 strategy. We apply our field-tested methodology to assess, define, and deploy a strategy that supports your organizational objectives.

- ASSESS your organization’s asset management competencies, including people, processes, and technology.

- DEFINE and develop a roadmap to improve these competencies, processes, and technology in alignment with your physical assets and organizational strategy, supported by a business case for change and expected ROI.

- DEPLOY the roadmap and build sustainable adoption and results by employing sound organizational change management practices.

Contact us today to explore how we can help you develop the foundational competencies your organization needs, and design an Industry 4.0 strategy that aligns with your Asset Management strategy.