Implementing a new process? Don’t forget to train people how to use it!

By Tara Denton Holwegner, CPLP, Life Cycle Engineering

When organizations want to improve operating performance they usually choose an approach like Lean, TPM, Reliability Excellence®, or Six-Sigma. Regardless of how an organization frames its initiative, these changes cost time and money because they require time to plan, design and execute the change. This investment is necessary to achieve the individual and organizational benefits improvements are expected to bring. Yet organizations often fail to make another investment in time and effort necessary for success – the investment of time and effort to train people how to use new processes.

In any improvement initiative, the way daily work is carried out will change to some degree. Organizations often create a team of trusted employees to revise or redefine how work is and should be done, drawing on the experience of subject matter experts within the organization. This new way of working will then be rolled out for the employees to own and bring about the results anticipated.

The team of people designing the new processes – the Subject Matter Experts (SMEs) – has the deepest knowledge of how the process should be executed. This team should also introduce the “new way of working” to those who will execute. However, teams charged with building new processes are not typically training or learning professionals. When the time comes for the process re-engineering team to roll out the new ways of executing work to the site, there is often hesitation. Imagine you are in a room with the elation of knowing your design work is done. All the new work processes have been completed! The room is covered with process flows and responsibility matrices. Suddenly, the question is brought up: Now what? Those flows and papers need to come to life, and how are we going to do that?

Bringing the process flows to life is a definitive point between process development and implementation. In essence, it’s preparing how you’re going to introduce a new process to others in a way that they will be able to immediately execute. Now, let’s take a step back and see what we’re really asking from our teams.

The Life Cycle Institute defines “learning” as “changing behavior to produce a result.” When we’re redesigning the way that people do work, we’re doing just that – we are asking people to do something in a different way in the name of improvement. We need to support the move from design to implementation by using what we know about how people learn.

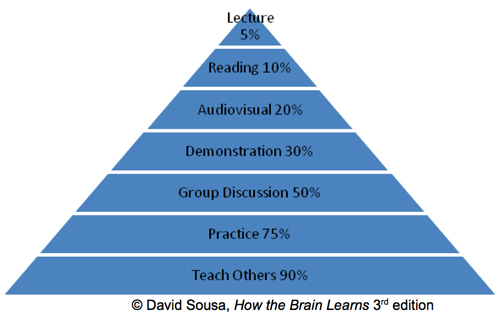

The image below shows how retention varies depending on the instructional method used. According to research published in David Sousa’s How the Brain Learns (3rd edition), lecture only yields 5% retention after 24 hours of being introduced to a concept. There is significantly more retention if concepts are introduced through demonstration and group discussion. Practice and teaching others have the greatest opportunity for knowledge retention, which is the key to actually practicing different behaviors on the job.

What does this mean for introducing a new business process? We need to move away from introducing the new way of work using slide presentations with images of the process flows, responsibility charts and bulleted steps of actions. Instead we need to introduce interactive, coaching-based plans to help people jump from learning to doing.

Life Cycle Engineering SMEs and the Life Cycle Institute learning professionals developed a process to help teams struggling with the jump from process design to implementation. The process involves a learning professional coaching design teams to define the following:

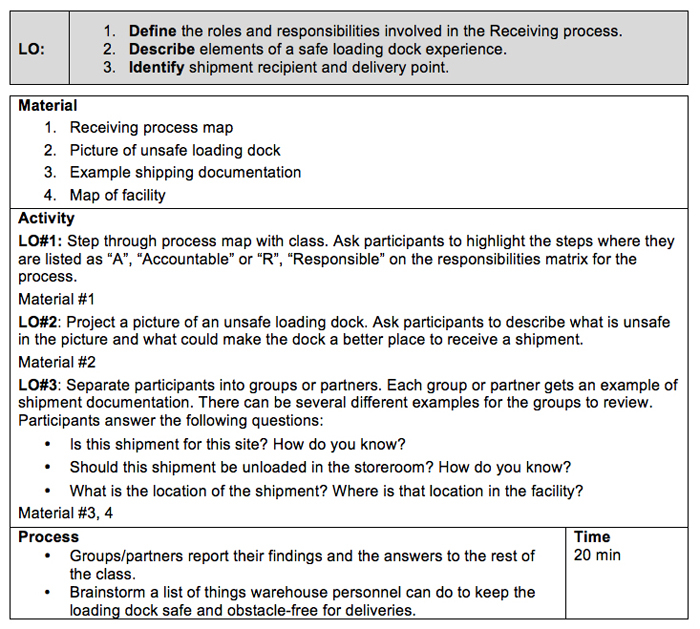

1. Learning objectives – using specific action words, define the knowledge or skills the learner needs to perform to execute the process

2. Create your MAP plan for each learning objective:

a. Material needed to support learning – what documents, instructions, examples, etc. will you need to reach the objective?

b. Activity – how will the learners practice or work with the new knowledge to reach higher levels of retention?

c. Process time – how will you debrief or ask the learner to reflect on the new material so it can be more easily retained?

3. Estimate the time it may take to complete the training

By defining these three elements for each of your processes, you will have a strong plan to lead your training efforts. Not only is the training plan a help when developing training, it is also an aid to the team member leading the training. If the plan is written with the “Activity” sections in sequential order, the team member can step through the plan with confidence.

Below is an excerpt from a training plan created to help introduce a new process. The objective of this example is to show how these plans can be written to sequentially step through the “learning objectives” section to draft the form, and to sequentially step through the “activity” section to deliver the training.

Typically, after a learning professional helps define the initial learning objectives and brainstorm several MAP plans, the team can work autonomously to develop their own MAPs. This is a double advantage, because it means the process subject matter experts are bringing their processes to life and designing the training consistent with how people actually learn.

Having team members create and deliver effective new process training maximizes the chances that people will leave the sessions prepared to change the way they work, paving the way for timely results from the improvement initiative. Other benefits to empowering teams to lead effective process training include more credibility for the training (the SMEs are leading it), greater determination of proficiency in the new processes and greater buy-in from the site to support the new processes in action.

Tara Denton Holwegner is a Learning Consultant with the Life Cycle Institute. Tara has designed and delivered formal and informal learning events and training material since 2001. Her passion for adult learning principles leads her to build learning products that meet business objectives and practice facilitation techniques that ensure knowledge transfer. Tara’s learning products have been named a finalist in training product competitions; her flexibility allows her to work on a range of projects, from advising a Fortune 500 company on an internal certification program to delivering Web training seminars. You can reach Tara at tholwegner@LCE.com.

© Life Cycle Engineering, Inc.

For More Information

843.744.7110 | info@LCE.com