Involving Operators in Your Equipment Maintenance Plans

By Michael W. Blanchard, CRE, PE, Life Cycle Engineering

Introduction

The success of your equipment maintenance plan (EMP) will depend on how involved operators were in its development and implementation. Are operator experience and abilities underutilized in your organization for the purposes of improving and sustaining asset reliability? Even if you don’t have an operator care (OC) program in place, you should consider operator care’s mitigation capabilities when a strategy is required to lower risk to the value stream. EMPs are also a great way to show the value that operators bring to the reliability-centered maintenance (RCM) team. Cross-functional collaboration is necessary to develop effective operator inspections. Operators are in a perfect position to develop, test and institutionalize routine equipment care and inspection tasks.

Involving operators in RCM analysis and generating solutions builds credibility for reliability improvement initiatives. The actions and behaviors demonstrated by an engaged operator will spread like wildfire. Operators are the first line of defense against the effects of unmitigated risk. Training them to identify symptoms of equipment in distress, adverse conditions and the actions to minimize their effects, is essential to improving and sustaining asset reliability. This paper explores how involving operators in EMP development and implementation will improve the impact on asset reliability.

Failure modes and effects analysis (FMEA)

The effectiveness of the EMP developed using FMEA depends on the level of understanding achieved through analyzing asset specifications, history and process data. Operator input is important when facilitating an FMEA. They can provide further details when analyzing the nature and root causes of failure. They will also validate any current controls, including any plant urban legends. Undocumented inspections should be treated with caution. They tend to be hit-and-miss and executed with a high degree of variability. However, if operator inspection procedures exist, they are subject to the same PM optimization process as maintenance inspections.

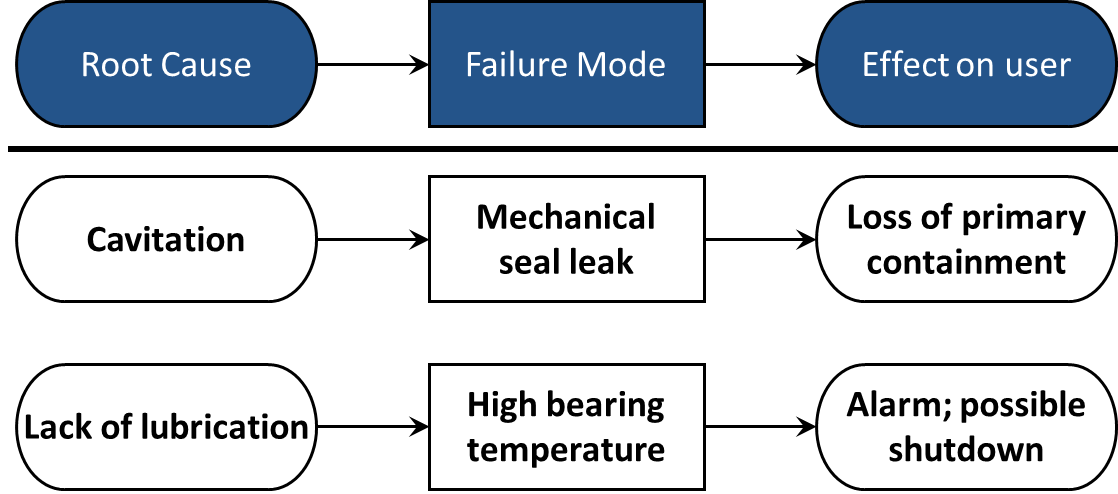

The equipment failure model used in FMEA is a three-part event as seen in Figure 1.

- Cause: reason for the failure

- Failure Mode: how the failure reveals itself

- Effect: impact of the failure

Figure 1 – Equipment failure model including examples1

Understanding equipment failure

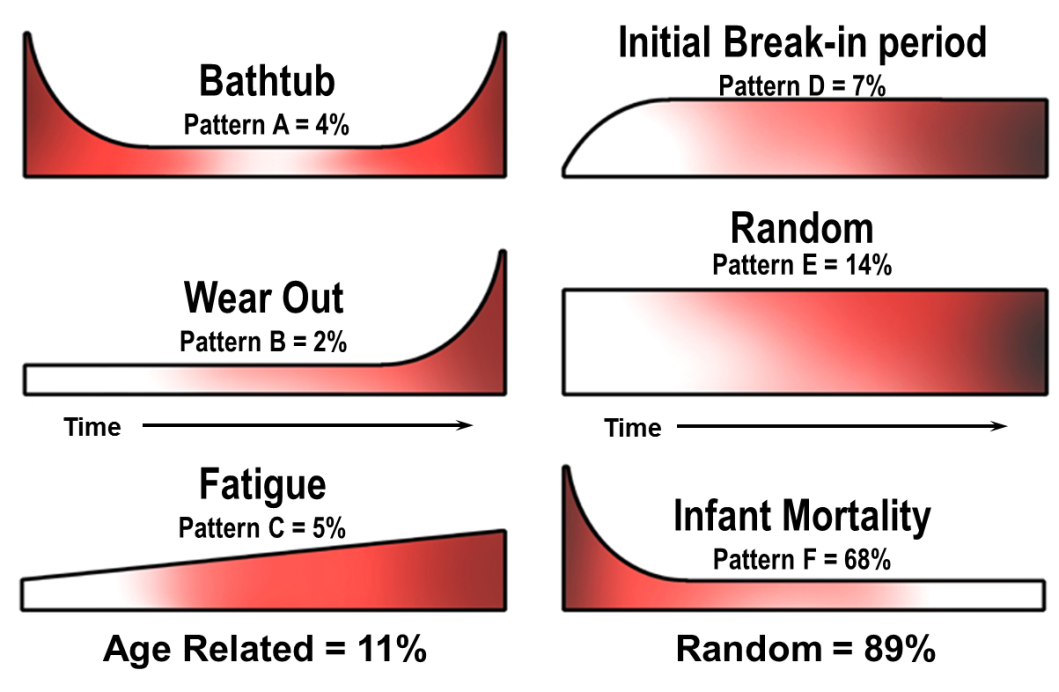

Unless the true nature of failure is understood, it will be difficult to identify the symptoms and root causes. As shown in Figure 2 below, approximately 89% of component failure patterns1 are random. Scheduling a time-based PM to address a random failure is not only inappropriate, it’s a waste of money. To effectively mitigate the risk of random failure modes (infant mortality, random, initial break-in), you need a hybrid strategy that includes operators.

Figure 2 – Failure Patterns (Source: John Moubray, Nolan & Heap) 2

You can minimize the risk of infant mortality and initial break-in failures by using standard operating procedures (SOPs) and acceptance testing to verify installations or repairs. Startup and shutdown SOPs should be thoroughly reviewed for content that may lead to equipment abuse or failure. Acceptance testing criteria should be evaluated for predominant failure modes and repairs. Ask your operators to update the SOPs and provide input to the acceptance testing policy.

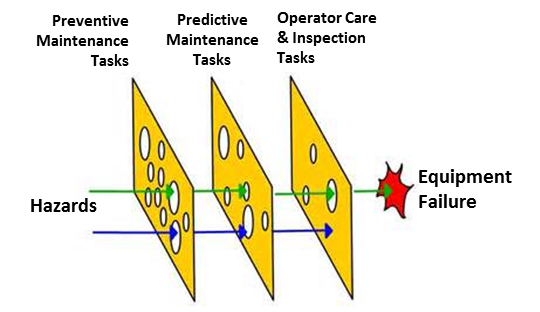

You can minimize the risk of random failures by adding a layer of protection to asset reliability. Figure 3 illustrates how operators can provide this protection. Through routine equipment care and inspections, operators identify symptoms of pending asset failure and take appropriate actions. The symptom, or signal of focus, must follow a degradation process that operators can monitor through inspection. Cross-functional team brainstorming provides probable symptoms that can be observed or measured. Operators will play a key role identifying possible distress signals, but most will require training.

Figure 3 – Reliability layers of protection

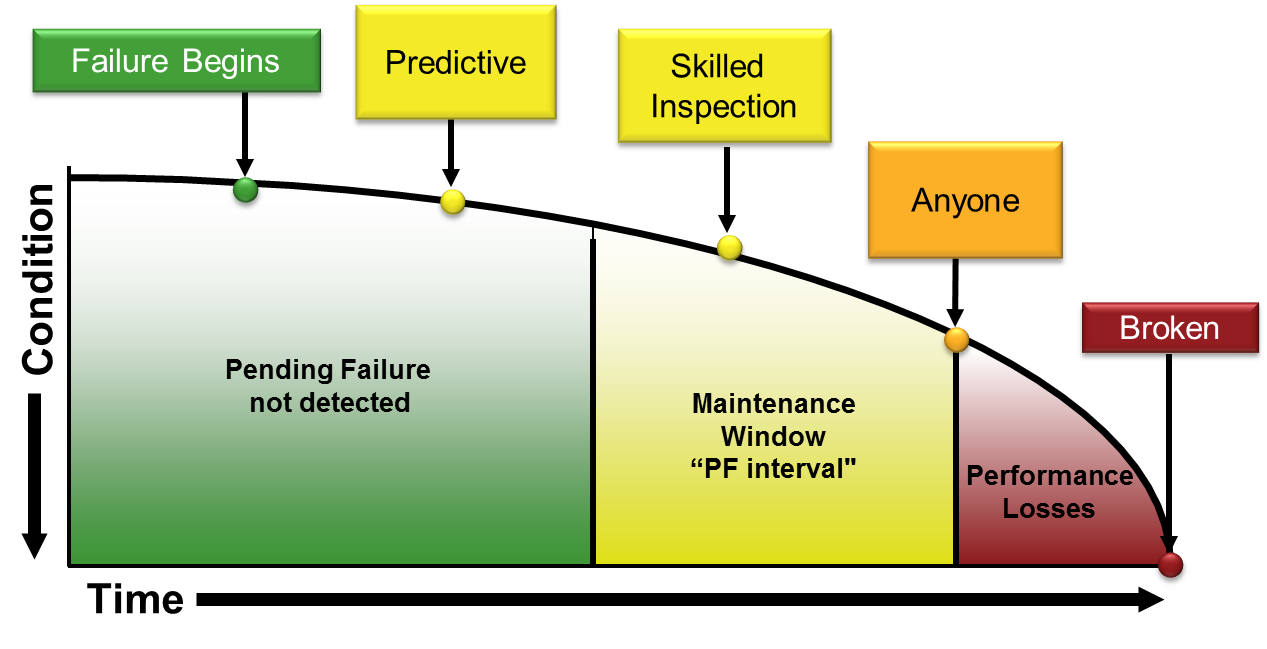

Operators are closest to the equipment and know when it’s running in a stable mode of operation. Besides on-line monitoring systems at their disposal, operators use their senses (i.e. sight, hearing, smell, touch) to detect abnormal signals usually associated with equipment in distress. The point of failure (PF) curve in Figure 4 shows how a symptom deteriorates over time, or cycles, and where operators can provide an additional line of detection should failure initiate between predictive maintenance (PdM) collection dates. The earlier the operator can sense these symptoms the more time the organization has to plan and execute a repair. In some instances, simple actions can resolve the cause of distress and the PF curve is extended. Operator inspections add a layer of protection against equipment failure and should be considered for every EMP.

Figure 4 – PF curve - Look for early signs of failure3

Risk Mitigation

Instead of planning only to identify maintenance tasks for further development, plan to identify cross-functional activities that have the greatest impact on risk, including operator care and inspection tasks. Routine equipment care and inspection may not be enough to drive the Risk Priority Number (RPN) to an acceptable level, but the RPN will drop even further when combined with a maintenance PdM task. The list below includes examples of operator-led tasks you should consider when selecting mitigation strategies:

- Identifying abnormal equipment signals and responding with appropriate corrective action

- Writing work requests to correct problems that were identified during equipment inspections

- Lubricating equipment

- Bolt tightening

- Cleaning

- Reducing sources of contamination

- Solving or tagging problems

- Adjustments

- Replacing filters, wear parts

- Collecting oil samples

- Participating in team meetings

- Providing improvement feedback

Equipment Maintenance Plan (EMP)

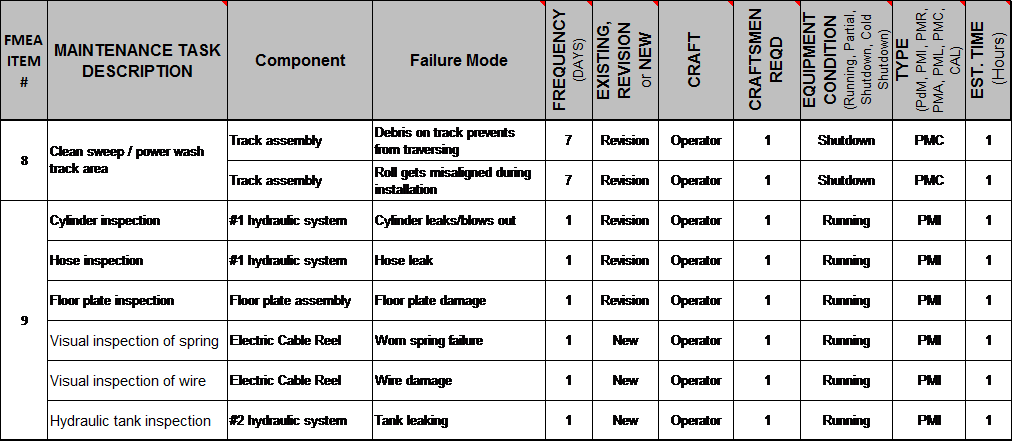

The Equipment Maintenance Plan (EMP) summarizes the tasks and resources needed to effectively preserve asset reliability. The EMP guides the development of the required operations and maintenance tasks by ensuring that it’s done consistently for all equipment. Routine equipment care and inspection tasks are added to the EMP the same as maintenance, as shown below in Figure 5. You may choose to separate the departments in the formatting to clearly show ownership and provide a summary of workload. When building the EMP, operators can help refine their tasks.

Figure 5 – EMP Template – Operator routine equipment care and inspections

Job Plans

Job plans for routine equipment care and inspection should be written with the same quality as maintenance. The job plans are documented and any data collected can be trended. A feedback loop is included in the job plans for continuous improvement. Operator inspection procedures should include simple corrective actions the operator can complete during the inspection along with the failure mode identification tasks. Operators can write the job plans as they execute the tasks. Provide them with training, plenty of examples and a template.

Operator-led inspections are meant to identify the symptom of equipment failure with enough advance warning that a maintenance technician can effectively troubleshoot the problem and take appropriate action. The criteria on the inspection sheet, or procedure, helps the operator to identify failure modes early enough on a PF curve to allow successful troubleshooting, planning and scheduling corrective action before equipment failure impacts the value stream.

Visual controls help operators immediately recognize work standards and other important information, as well as deviations from those standards. The goal is to get the appropriate information or standard as close to the point of action as possible. Examples of visual controls include:

- Match marking torqued fasteners

- Marking (high and low) reservoir and tank levels

- Marking gauges with normal operating ranges

- Marking piping flow direction

- Color-coding content in piping and vessels

- Marking direction of rotation on drive and driven equipment

- Indicators to identify when filters need to be replaced

- Labeling each lube point and color-coding it to identify lubrication

Conclusion

Operators can make or break your reliability program. Involving them in EMP development and execution will require time, training and continuous improvement support. Building a strong relationship with the process owner provides the opportunity to teach them the building blocks of a reliability-centered culture. It’s imperative to gain their support before approaching operators and support roles. Operators are the first layer of protection against the effects of adverse conditions. Training operators to identify symptoms of equipment in distress, adverse conditions and the actions to mitigate their effects, are essential to improving and sustaining asset reliability.

References

- Life Cycle Institute’s Predictive Maintenance Strategy course

- Source: John Moubray, Nolan & Heap

- Life Cycle Institute’s Operator Care course; slide

Michael Blanchard is a Reliability Engineering Subject Matter Expert with Life Cycle Engineering (LCE). He has more than 25 years experience as a reliability leader in a variety of industries. Mike is a licensed Professional Engineer, a Certified Reliability Engineer, and a Certified Lean-Six Sigma Master Black Belt. You can reach Mike at mblanchard@LCE.com.

© Life Cycle Engineering, Inc.