Macro-Managing Your MRO Inventory

By Doug Wallace, CPIM, Senior Consultant,

Life Cycle Engineering

The mission of the MRO warehouse is to have the right parts at the right place at the right time. Too often that objective is achieved by simply stuffing the storeroom to the gills. Some organizations do a better job of trying to determine realistic stocking plans based on criticality, estimated requirements, supplier lead times, and other variables, but then fail to review them periodically to ensure that the assumptions used in developing the stocking plans are still valid.

Either way, the end result is the same: over time, inventory gets out of control, and some difficult decisions have to be made. Often those decisions are made with no strategy or overarching goal other than cutting inventory as quickly as possible, and no real understanding of the impact they cause on production or reliability. The results can actually be counterproductive, leaving Operations exposed to critical material shortages and significant production delays!

Whether in steady-state or crisis mode, trying to control inventory by micro-managing it at the item level is not the right approach. The need to support Maintenance and Operations has to be properly balanced with the responsibility to minimize the costs associated with carrying that investment. A top-down approach that starts by “macro-managing” your inventory produces a more integrated strategy that results in less total cost to the company.

First, you need to ask yourself, “How much inventory do I have?” If you are in a position in the organization that the storeroom reports to, you should know. You are the steward of those resources and it’s your responsibility to manage them effectively. If you don’t know what you have, that will be difficult if not impossible.

Next, ask yourself, “How much inventory should I have?” This is a tougher question to answer, but it’s much better to determine that target yourself than to be told by someone else who has no direct responsibility for the inventory on a day-to-day basis.

There are a couple of ways to estimate how much inventory you should have. I prefer Turnover, which is a ratio of dollars issued to dollars of inventory. Turnover directly relates your level of inventory to the level of demand for that inventory. Best-in-class targets for Turnover in an MRO environment are between 2.0-3.0 turns per year.

Turnover is most effectively improved through better management of the storeroom investment, but most organizations will find that even modest improvements in the metric would require eliminating so much inventory that the results could be catastrophic!

Achieving or approaching best-in-class inventory benchmarks almost always requires a number of carefully developed strategies and tactics implemented concurrently over a significant period of time. To help determine which approaches will be most effective for your situation, it is helpful to start with the steps below:

1. Identify Obsolete Material

Almost every MRO storeroom has some parts that are for equipment no longer in service, have been redesigned, or are otherwise unusable. Any items found to be obsolete should be flagged in the system and physically segregated.

2. Identify Excess Inventory

Excess inventory is stock of usable materials that exceeds short-term anticipated requirements. For most items, the highest the inventory should ever go is the sum of the Reorder Point plus the Reorder Quantity. Excess is simply the amount of on-hand inventory above that highest expected level.

3. Prioritize the Active Inventory

An ABC analysis will determine the items that have the greatest impact on service and investment, and therefore identify the ones that you should spend the most time on. Make sure to exclude anything identified as obsolete.

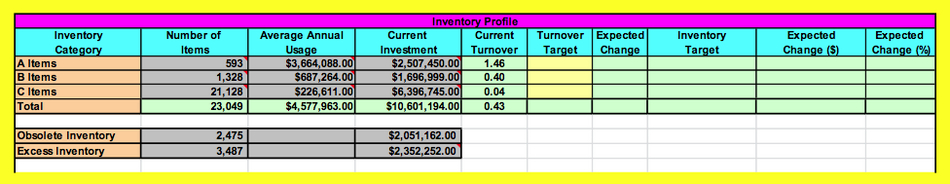

4. Establish a Baseline

A baseline profile uses the results of the above activities to depict a high-level view of the current state of your inventory. It shows the amount of your investment you have tied up in obsolete and excess material. It shows how your inventory is distributed by activity level and how quickly materials are turning over at an aggregate level.

Below (Figure 1) is an example of a baseline profile taken from an actual case study.

Figure 1: Baseline Inventory Profile

Once you understand the makeup of your inventory, you can determine which tactics are most likely to reduce your inventory without adversely affecting service.

Start by eliminating any obsolete materials. They have no impact on service, but depending on your carrying costs can be expensive to keep. You may need to lessen the impact on bottom-line plant results by establishing a monthly scrap budget and spreading the expense over a period of time, but determine the best way to dispose of it (scrap it, recycle it, sell it, donate it), and get rid of it as soon as possible so it’s out of your inventory.

Evaluate excess inventory, starting with the highest values first. Each item needs to be reviewed to determine the cause of the excess and the right course of action. For any item that is overstocked, specific action plans should be developed to scrap, sell, use up, or otherwise eliminate the excess inventory. As these plans are executed, the associated value of the excess material should come out of your inventory.

Next, review your stocking plans, starting with the “A” items that have the greatest investment. By definition these items are more active, and therefore can be managed more aggressively. Lowering the Reorder Point will reduce average inventory, but it also impacts service. Lowering the Reorder Quantity increases reorder frequency, but also reduces average inventory levels without impacting service. Making changes to stocking plans on “B” and “C” items will help as well, but generally have far less impact.

Look for items that don’t need to be in inventory at all. Materials for PMs (e.g. lubricants, filters, etc.) should be identified on standard PM job plans and demand for these items can be predicted based on the frequency of the PM. Some material requirements can be anticipated based on Predictive Maintenance technologies. Work on non-critical assets can be planned and scheduled and the materials ordered as needed.

Try to establish consignment or vendor stocking arrangements to get other items out of inventory but still assure adequate supply. These arrangements significantly reduce the lead time and also increase Turnover since they are issued through the storeroom but don’t get reported in the inventory.

Look for potential Free Issue materials. These are typically low value/high volume items such as fasteners, fittings and consumable materials where usage doesn’t need to be tracked. They are usually expensed at the time of purchase so the on-hand balances don’t need to be maintained, and therefore the value of the material does not show up in the storeroom investment.

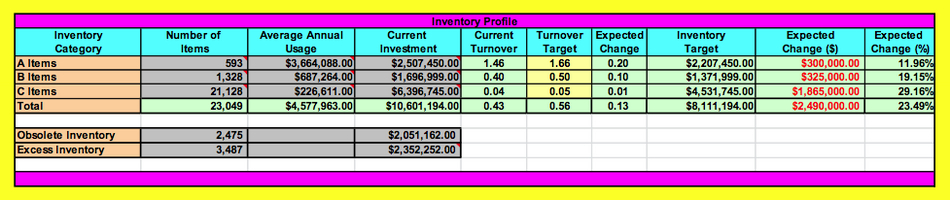

With these plans in place, it should be possible to establish target inventory levels, which can be translated into revised turnover goals. The updated inventory profile below (Figure 2) shows how the client in the case study estimated the impact of their inventory management activities.

Figure 2: Estimated Impact of Inventory Management Activities

Reducing their investment by almost 1/4 was only expected to improve Turnover by about a third, but eliminating nearly $2.5 million of inventory would still be a significant achievement!

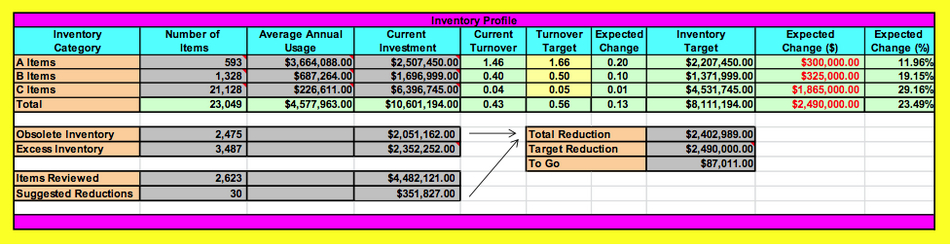

As they reviewed individual items they monitored their progress each week as shown in Figure 3 below.

Figure 3: Monitoring weekly progress

Within three months they were able to realize nearly their entire goal by prudently but aggressively following the steps above. In fact, having achieved their initial target of $2.49M, they went on to identify an additional $1M of material that they believed could be removed over the next 12 months.

By successfully “macro-managing” their inventory this client was able to meet – and exceed – their inventory reduction target, improve their Turnover, and significantly reduce their carrying costs with no appreciable impact on service.

Doug Wallace is a Senior Consultant and Materials Management Subject Matter Expert for Life Cycle Engineering (LCE). In addition to his materials management expertise, Doug is knowledgeable in planning and scheduling and operator care best practices. He is also certified in Prosci’s Change Management methodology. Doug can be reached at dwallace@LCE.com.

© Life Cycle Engineering

For More Information

843.744.7110 | info@LCE.com