Maintenance Planners: At the Center of It All

A topic from our popular Maintenance Planning & Scheduling course

Successful maintenance organizations are built around effective communications between all functions within the organization. Therefore, maintenance planners must establish strong relationships with key functions in the organization. Supervisors, Operators and Maintenance Technicians all play key roles in the success of planning and scheduling. Relationships between employees in these roles must be nurtured in order to avoid departmental silos, communication barriers and increased down time.

Role of Planner/Scheduler

The basic goal of planning and scheduling is avoiding delay. The role of the Maintenance Planner is to improve work force productivity and work quality by anticipating and eliminating potential delays through planning and coordination of labor, parts and material, and equipment access. It takes a professionally trained Maintenance Planner carefully planning and scheduling work to maintain the designed reliability of equipment. Job plans created by the Maintenance Planner are intended to ensure or extend the life expectancy of equipment therefore aiding in the total reduction of maintenance cost and increased output of product.

Reporting to the Maintenance Manager and maintaining liaison between Operations and Maintenance, the planner is responsible for planning, scheduling, and coordination of all plannable maintenance work performed within the facility. Through supervision of the Maintenance Administrator, the planner is also responsible for maintenance of records and files essential to meaningful analysis and reporting of maintenance-related matters.

By definition of the role itself, Maintenance Planners are required to interact and communicate regularly with Operations and Maintenance. Not only is the maintenance planner’s role to interact with these groups, he serves as an integral member of the relationship between the groups by acting as a liaison between them.

Responsibilities and Duties

The planning and scheduling function is the hub from which all plannable maintenance activity is coordinated. It is the process of describing a job in terms of how it is to be performed and what resources will be required. It involves a broad spectrum of activity.

The Planner must know the job well enough to describe what is to be accomplished and estimate how many labor-hours will be required. If the Planner doesn’t know requirements, the assigned crew will not know the expectation.

In performance of her/his duties, the Planner:

- Will be the principal contact and liaison person between Maintenance, Operations and other supported departments. In this capacity, the planner ensures that all internal beneficiaries of Maintenance receive timely, efficient and quality service. He also takes a continuing interest in internal needs. With keen awareness of the situation (schedule, problems, etc.), the Planner is able to help Operations balance their need for daily output with their need of equipment reliability through proactive maintenance.

- Is responsible for long-range as well as short-range planning. Long-range planning involves the regular analysis of backlog relative to available resources. These two basic variables must be kept in balance if a proactive maintenance environment is to be established and sustained.

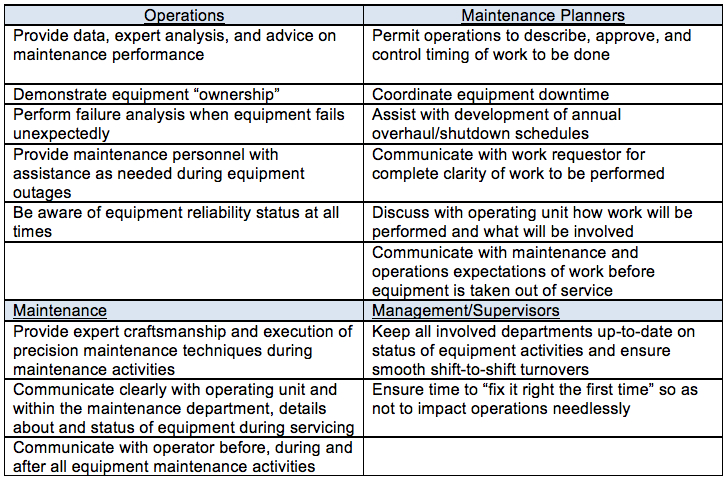

Every working relationship requires two-way communication, shared responsibilities and compromise. The maintenance world is no different. As you read through the expectations listed below, think about your own organization and how your relationships stack up.

Relationship Expectations

Benefits of the Relationship

When relationships between Maintenance Planners, Operations, the Maintenance department and Management run smoothly, there are great benefits for all involved.

Operations

- Reduce cost of maintenance while improving service

- Minimize downtime and interruptions to operations

- Render better service to operations by performing most important jobs first (as determined by operations)

- Apply technical and maintenance experience to analysis of each job

- Provide orderly procedures for processing work to prevent work orders from getting lost:

A. Maintains accurate backlog status

B. Reports completion promptly - Provide expert maintenance advice to operations through maintenance planner

- Provide a single contact for all in-process, scheduled, and emergency work (area supervisor or functional supervisor)

- Require that operating personnel anticipate repair work before jobs become emergencies

Maintenance

- Permit advanced determination of labor resources needed and time required to complete each job, which aids the maintenance supervisor in measuring the performance of his/her personnel

- Allow elimination of delays due to waiting for information, materials, equipment, other skills, tool, etc.

- Provide an overall plan for the supervisor on which to base his/her pre-thinking and pre-planning for day-to-day work and future work

- Provide the cooperation necessary in connection with each job to do work as prescribed by operations

- Provide a central source of information concerning maintenance work, equipment, and equipment repair

- Allow the supervisor to devote closer attention to supervision of work in the field or shop

- Provide special tool and equipment requirements

- Reduce clerical work of the supervisor

- Permit advance determination of the number of labor resources needed in a given area or location

- Reduce the number of job interruptions once work is started

- Establish job goals for the work force

- Predetermine and arrange for required shop work

- Apply specialized ability to the planning and scheduling of shutdowns

Management

- Reduce total cost of maintenance while improving conditions of equipment and operating facilities

- Permit acc urate forecasting of labor and material needs

- Permit immediate recognition of labor shortages and excesses

- Enable management to level out peak workloads

- Provide factual data required for evaluation of performance and corrective action as needed

- Provide close and constant liaison between operations and maintenance through the maintenance coordinator

- Provide a full day of productive work for each tradesperson and thus increase productivity through the elimination of delays

- Permit more accurate collection and analysis of cost and assure an economic level of maintenance with less interruption of production

- Highlight for analysis requests for work of questionable justification

- Provide for maximum delegation of authority to permit decisions to be made by those who have firsthand knowledge of the problem

Developing a close relationship requires a commitment from all parties involved for long-term success. Ineffective relationships within the groups listed above can lead to a reactive, rather than a proactive, maintenance culture. Frequent and effective communication is a requirement for building strong relationships and creating alignment among groups.

© Life Cycle Engineering

For More Information

843.744.7110 | info@LCE.com