Reliability Excellence® (Rx) Assessment, Master Planning and Business Case Development Process

Download Rx Assessment Master Planning and Business Case Development Process (PDF)

Download Rx Assessment Master Planning and Business Case Development Process (PDF)

Whether facilities are new or old, large or small, simple or complex, reliable operations require a shared set of values, common performance expectations, proven work processes and well-established measurement criteria. For these operations, reliability becomes a competitive advantage by directly impacting safety, capacity, quality and cost. Life Cycle Engineering (LCE) has developed assessments, master planning and business case development process to help clients achieve this competitive performance level.

By using LCE’s proven process our clients can determine how well they execute Rx best practices, identify the value associated with their application and determine the actions required to achieve sustainable improvements. Our process is based on a standard set of questionnaires that quantify approximately

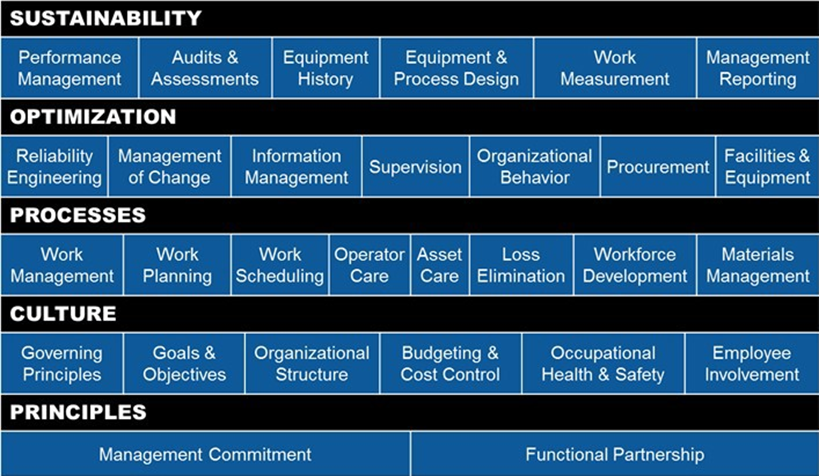

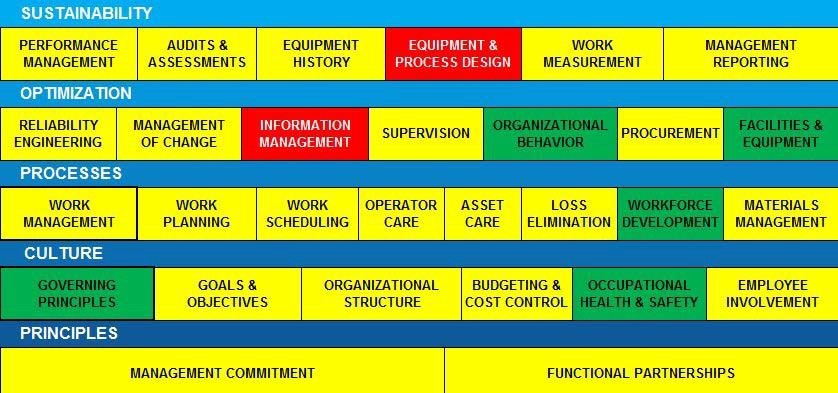

650 attributes of the manufacturing operation including fixed assets, work processes, information systems and human resources. We align these attributes to the 29 elements of our Rx Model and rate them against our database of Rx best practices. In this process we work with our clients to review and benchmark their organization’s operational and financial performance. We partner with our clients to identify and prioritize improvement opportunities and use this information to develop the implementation Master Plan along with the business case to justify the project.

Exhibit 1. Reliability Excellence (Rx) Model

This process addresses the operation holistically and promotes reliability throughout the organization. Although there are many activities that are primarily controlled by the maintenance organization, our experience has shown that a collaborative relationship between maintenance and other departments, such as engineering, operations, production, quality, finance and regulatory, is critical to success. The integration and interdependencies that exist between these other functions and maintenance can greatly impact the potential of Rx and overall business performance. Additionally, we have found that in order to achieve Rx, executive management must understand the value that reliability contributes to the business and actively participate in the cultural change and application of Rx best practices.

The many steps in the process – including data gathering, observations, on-site interviews, data analysis, planning and building the business case – increase awareness throughout the organization of the impact reliability can have on the business. Participation in the process facilitates organizational alignment as the future state becomes clearer and the stake each department/individual holds in the improvement process is defined. This alignment/buy-in is critical to the effective implementation of cultural and behavioral change associated with adopting Rx best practices.

Our experience executing more than 350 Rx assessments confirms that the process provides immediate benefits to the client’s organization. In addition to building organizational awareness, alignment and buy-in, the process delivers:

- Widespread understanding of the current state of operations and the gaps that exist between the current state and Rx best practices

- Leadership commitment to the initiative

- A defined roadmap – the Master Plan – that will lead to the future state

- A cost/benefit business case that supports the financial justification to undertake the initiative

- The identification of prospective change agents who will actively drive and sustain the new organizational culture

Once the organizational alignment exists, the true value can be recognized by implementing the Rx Master Plan.

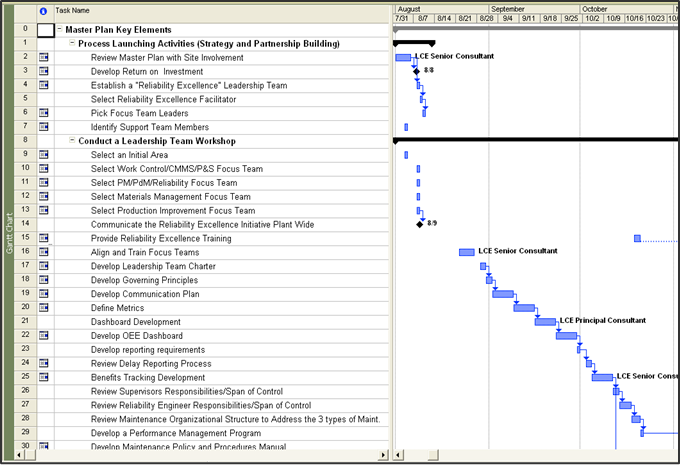

Exhibit 2. Sample Excerpt from Master Plan

By implementing a Rx Master Plan our clients have recognized improvements such as capacity increases greater than 45%, greater than 10% reduction in cost of goods produced, maintenance cost reduced by more than 30%, improved safety and regulatory compliance, substantial avoidance of capital investment and extended asset life cycle. These business improvements are the direct results of a change in culture combined with the application of Rx best practices. Reliability is achieved not only in the equipment/fixed assets, but also in the work processes, the information systems, and organizational behavior.

LCE’s assessment approach analyzes the current state of your operation’s performance, compares it to best-practice benchmarks, and provides the foundational information to develop a gap closure plan/timeline along with a cost/benefit business case for execution and attainment of the desired future state.

- In the first step in the process, LCE will analyze performance and financial data associated with the current reliability and asset management practices from data provided.

- Next, LCE will coordinate with the client point of contact to outline the assessment plans and develop schedules for interviews and a tour (in-person and virtual) of each site.

- During these assessments LCE will:

- Document observations gathered from in-person and virtual interviews and tours of operations.

- Conduct interviews (45-60 minutes each) with a cross-functional team of approximately 40-80 site personnel, based on plant size, leveraging LCE’s standard Rx maturity level questionnaire that includes all 29 elements of our Rx Model.

- Review examples of processes, procedures, and documentation as well as IT systems/infrastructure associated with operations and reliability, covering the 29 elements of LCE’s Rx model.

- Using the data gathered on-site and the pre-site evaluation, LCE will analyze the site’s reliability and operational practices compared to industry benchmarks for each of the 29 elements of our Rx Model. As a result of our analysis, we will determine your overall maturity score.

- Identify any “Quick Wins” that can be implemented in parallel to the implementation of best practice business processes.

- Hold an initial out-brief meeting with site leadership at the completion of the assessment to review themes, quick wins, and potential opportunities for closing the gaps between current state and best practices.

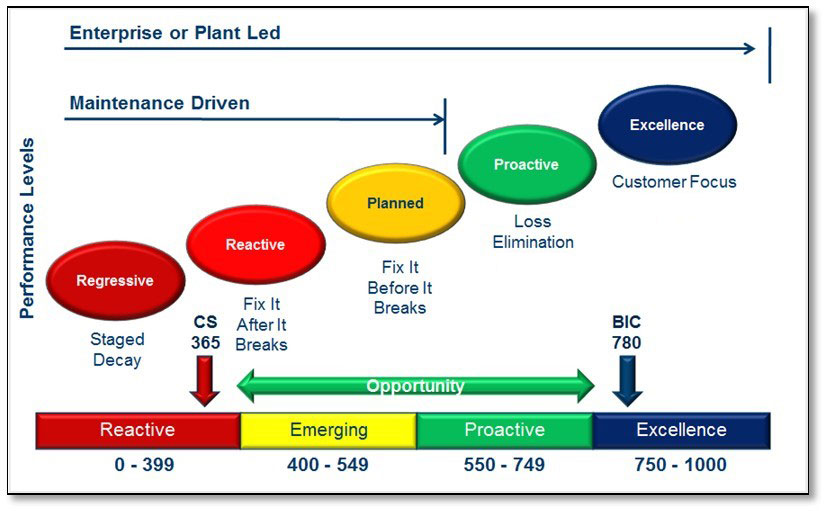

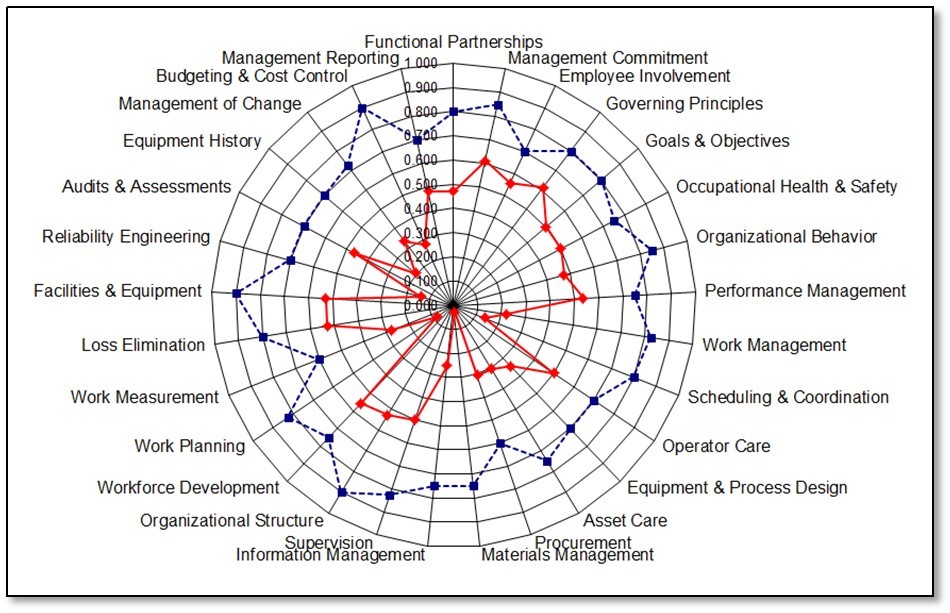

- Each evaluated element of the assessment is color-coded for prioritization and benchmarking purposes, as shown in Exhibit 3. Each element is then graphically mapped to show gaps between current state and best-practice benchmarks, as depicted in Exhibits 4 and 5.

Exhibit 3. LCE Rx Assessment Maturity Levels

Exhibit 4. Sample Gap Analysis

Exhibit 5. Rx Model with Sample Scoring

- The LCE assessment team will then complete the detailed analysis consisting of:

- Final analysis of the current state of reliability and operational maturity compared to best practices.

- Identification of opportunities to improve asset management / maintenance practices and operational performance.

- Development of a draft Microsoft Project implementation plan / schedule for execution of the program at the site.

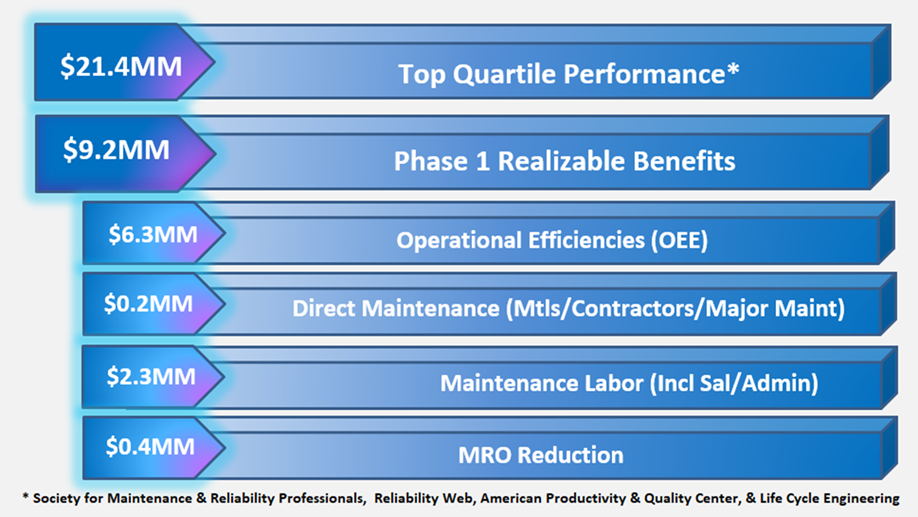

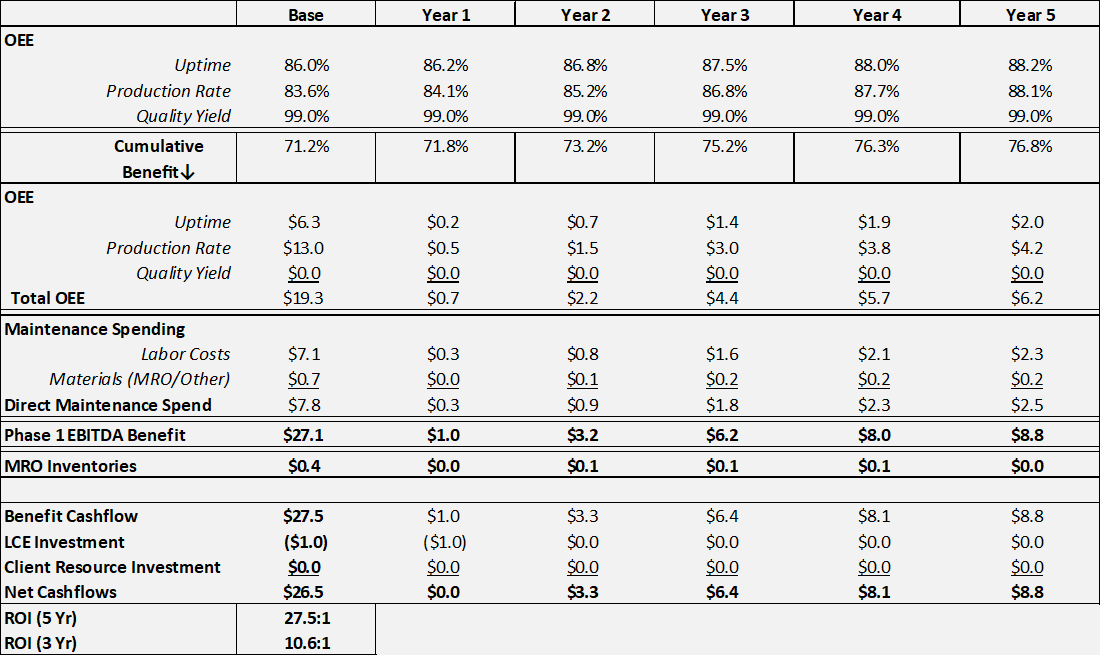

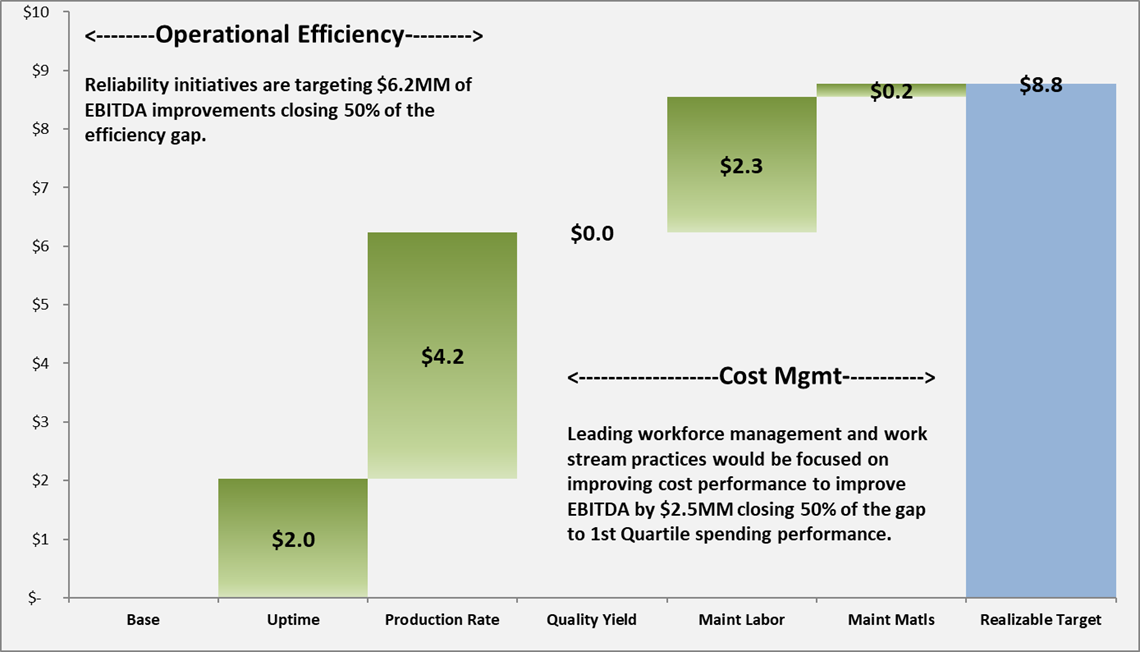

- Development of the cost / benefit business case with cash flow / ROI for implementation. (Shown in exhibits 6, 7 and 8.)

Exhibit 6. Sample Opportunity Analysis

Exhibit 7. Sample Cash Flow / ROI

Exhibit 8. EBITDA Impact

- Finally, the LCE assessment team will review the draft presentation with the site team members to finalize assessment deliverables, including plausible “Quick Wins.”

By using LCE’s proven process our clients can determine how well they execute Rx best practices, identify the value associated with their application, and determine the actions required to achieve sustainable improvements.

About LCE

As a leading maintenance and reliability solution provider for over 35 years, Life Cycle Engineering (LCE) (www.LCE.com)

helps public and private enterprise gain increased profitability through greater capacity, lower operational costs, and

decreased downtime. By combining a range of industry experts, unique processes with proven success, and a

comprehensive array of educational courses, LCE has gained reputable status as the premier provider of innovative

and successfully executed reliability and maintenance solutions worldwide.

For More Information

843.744.7110 | info@LCE.com