The Eighth Operational Waste - Employee Involvement

People have written about the “Seven Deadly Wastes” in organizations. However, many have missed one of the biggest opportunities for quick improvement by overlooking one of the deadliest wastes, right under their noses. This would be the inability to fully utilize the knowledge and skills of their employees. With recruitment efforts and training budgets continually increasing in order to “get the right people on the bus,” once they are aboard, we often overlook the value of their knowledge, skills and attitudes to build on their strengths. As Jim Collins states in his book “Good to Great”, you need to evaluate and develop the peoples’ assets. The goal should be to put the right people in the right seats to drive your bus to success.

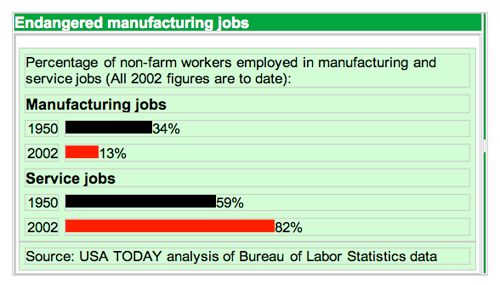

This article will review the original “Seven Deadly Wastes,” and will discuss the importance of getting everyone in the organization involved to improve all aspects of the operation, including reducing those seven deadly wastes. The Eighth Waste – Employee Involvement is the linkage between Lean and TPM. We will talk about how to improve the US manufacturing world by taking advantage of our most valuable resource – the employees. The most important step in helping preserve our country’s manufacturing industry is to instill ownership in our people. There needs to be buy-in to take advantage of people’s abilities and realize the benefits to reduce waste. It will take a lot of hard work to save prosperous jobs for our kids so they don’t have to grow up to learn how to say “would you like to super size that?” Our society is quickly becoming a service industry due to the mass exodus of manufacturing jobs.

First we will review the standard Seven Wastes briefly.

The “Seven” Wastes:

Overproduction

If the organization does not use a pull system to produce based on your customers needs then you will most likely produce more finished goods than you can readily sell. You may also undersell or ship late not meeting your customers’ demands. You should strive to meet 100% of your Customers delivery compliance schedules. The overproduction is a waste since it ties up valuable assets and causes your Materials and Logistics organization to order more raw materials and produce more WIP that compounds with the Carrying Costs. Do you ever have to store Raw, WIP or Finished goods in trailers because you have run out of warehouse space? This is a sure sign that you are producing the wrong mix of product compared to your sales forecast or your customers’ pull requirements.

Delay (Waiting)

This is again a sign of not having the right mix of Raw or WIP materials on hand when you need them. This can be in productive material or MRO components. How often are your crafts people waiting for the right spare part to fix equipment? Do they ever have to cannibalize other pieces of equipment to get a critical machine back up and running to meet a customer’s need? When was the last time you worked on your vehicle or lawnmower and you reached for a wrench and it wasn’t there? “Someone” didn’t put the tool back where you wanted it. Now you have to stop working on your task and search for the right tool to complete the job. You need to 5S your workstations to eliminate these external delays. Another form of waste is an unbalanced work process where one person has to wait for the upstream operator to finish their task. Takt time is used to balance the work between operations to meet the customers’ needs in an efficient manner. Watch a Nascar pit crew change 4 tires, clean the windshield and fill the tank in 13 seconds; that’s a balanced operation.

Transport

All RFQ’s for suppliers should be evaluated on a landed cost basis. Many buyers forget about the cost to transport parts – that’s logistics responsibility, right? That’s the easiest way to document the cost to transport raw materials to your dock. Now try to calculate the cost to transport your Raw WIP and Finished goods throughout your facility. Having a one-piece flow layout will reduce that cost and increase your Turns. Using a Process Flow Diagram or a Value Stream Mapping process will help document how inefficient and costly some layouts can be.

Processing (Inefficient)

Inefficiency pretty much says it all. Using poor scheduling practices or running incapable equipment or tooling will cause process losses. That is why Standardized Work Practices are so important. Using a cross-functional team to validate SWP’s or Standard Operating Procedures SOP”s is the most sustainable method to instill ownership and buy-in within the ranks of the most valuable asset you have – the people performing the work.

Inventory

Excess inventory can be very costly. If the financial organization values your Carrying Cost at 30% and you have excess inventory in Raw, WIP (work in process) and Finished Goods then there should be formal plans that reduce your Inventory to increase your Turns. Inventory Turns is a standard metric to evaluate the effective utilization of your assets – Material Costs. Excess inventory can be a result of long lead times from your suppliers - internal or external, or the respective reorder triggers. Just In Time delivery and Kanban actions can reduce this excess cost. An inefficient workflow can also induce costly inventory into the process.

Motion (Unnecessary)

Non Value Added wasted efforts are like attorneys. You don’t realize how much time and effort (cost) you are wasting until you analyze the internal and external delays. Using a “dance chart” to document all of your travel time will illustrate how much time and effort you are expending without adding any value to the process or product. This will help you recognize the wastes in ineffective layouts, tooling or practices. Remember the pit crew? They review their performances using a bird’s eye camera view to evaluate any wasted movements and the Motion, Time and Movement of each team member to balance the total operation.

Defects

If you have a plan to become world class to achieve a 6 sigma level of First Time Quality then you understand the value of 1 PPM in scrap. Enough said. Just think of how you expect the quality of the products you buy every day at the grocery store and equate that to your customers’ expectations of the defects you deliver to them. You should deliver to your customers just like you expect quality in your every day use of consumable products. When you drive down the highway and you veer out of your lane, the rumble strips make you aware that you have gone out of control. If you don’t make an adjustment and you continue to drive further out of control you will soon hit the guide rail that prevents you from going into the oncoming traffic – this is going out of spec. Or better yet, how would you feel being operated on in a hospital that delivers services with a 99.9% quality rate, not bad huh – that’s 1000 PPM? Would you want to get a bypass there? Making product that is out of spec is very costly.

The Eighth Waste: Now for the good stuff!

Lack of Employee Involvement / Operator Care – Provided you have the right people in the right seats on the bus, your human resources are your most valuable assets.

Why do we NEED to involve the people in the continuous improvement process? There are numerous reasons such as: Safer Work Environment, Job Security, Improved Quality, Increased Productivity, Improved Skills and maybe the most important reason in the US manufacturing community – Competitive Viability. With the systemic outsourcing of American manufacturing jobs, it is imperative that we improve the quality of our work and eliminate waste through the involvement of the employees.

First things first, there must be a reliability effort in place in conjunction with an Operator Care initiative. The equipment must be in a repairable state for the people to care for it. The whole intention is to create an environment where the people want to take ownership of their equipment. If the equipment is not reliable then the other lean tools and OC initiatives will not be as successful.

Let’s talk about each of these OC benefits. We need a safer work environment not just because the safer workplace creates a more productive facility, but also because of the increasing costs of health care and lawsuits / insurance. Healthcare costs are increasing at a rate of three times the cost of inflation. Accidents and lost time are expensive. A healthy employee is a more productive worker. Absenteeism is very costly; if your overtime rate is above 10% then you are spending way too much in a premium that doesn’t add any value to the cost of your products or services. The days of working for the same company for a lifelong career are long gone, at least for now. Job security also contributes to higher efficiency and morale. If the people feel that they are part of the family and don’t have to worry about the security of their job, they are much more likely to accept ownership and giveback to the hand that feeds them. Morale is a contributor to productivity, safety and quality. Creating an environment where the people want to take ownership will result in a competitive advantage similar to the mini-mills that have revolutionized the American metals industry and created more jobs while providing better quality products at a competitive price – job security!

Improved quality is pretty easy to understand. If you are old enough to remember when you picked up a trinket and it said “Made in Japan” it was synonymous with cheap of junk. Now look at how the Japanese products have continuously increased their market share over the last 30 years. They did that by listening to people like Dr W Edwards Deming, Shigeo Shingo and Seiichi Nakajima and implementing their process improvements. Productivity improvement will be a result of the involvement of the people. One of the most widely recognized measures of productivity is the Overall Equipment Effectiveness metric. This drives the organization to strive for 100% quality and higher utilization of the assets at their purchased capabilities.

When dealing with people we need to be effective not efficient. We need to be efficient with equipment and processes but more deliberate when dealing with changing the way people think. This requires more effective training to develop those people skills and create a more proactive workforce. Once they have accepted ownership and treat the machines the way they treat their personal vehicles, then the results will pay off. The plan is for them to “Clean to Inspect, Inspect to Detect, Detect to Correct, Correct to Perfect”. If there hasn’t already been a 5S implementation the work place should at least be clean and organized. There needs to be a mind set, just as I used the misplacement of the wrench as an example, that there is a place for everything and everything is in it’s place. People know exactly where their toothbrush and toothpaste are when they need them. Why is it any different at work?

Once the work environment is worker friendly then the Autonomous Maintenance will flourish. The people have to treat their entire work environment like they treat their home. I’ll never forget walking through the plant with the plant manager and another young engineer a few decades ago. The young guy had a dip in and spit into a sewer grate in the plating area. The plant manager went off on him and asked him if he spit on the floor in his house. Why do people complain about the cleanliness of the bathroom at work when they are the ones that make it dirty? They have to understand that it is their role to keep their place of work clean just like they do at home or in their vehicle. They expect their car to be clean when they get their oil, lube and filter changed at the service station. They need to accept the accountability and that it is their role to do the same at their home away from home.

So how do we manage change at work and convince people that we need to change our way of thinking and doing business in the shrinking US manufacturing community? As Steven Covey helps us understand, we need to convince our fellow workers, at all levels, that we must start with an end in mind. We need to become more effective in getting the results we need and to do it repeatedly – sustain the changes to eliminate the wastes. Our competitors are not going to sit on their laurels and wait for us to improve. That is why the likes of Shingo give us the recipe for success. They don’t believe that we will be sincere and really embrace the need to continue to tear down and rebuild our processes to continue to improve. They think that we will water down the purity of the Lean tools and not succeed in our quest or need to change and eliminate the wastes that are making us non-competitive.

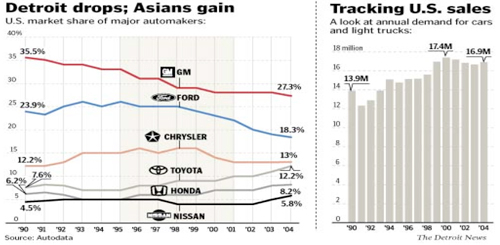

Again, look at the market share of the automobile industry in the US. The Japanese manufacturers just keep eating our lunch. If you can’t already tell, I used to work for GM. In the late 70’s GM enjoyed a market share of greater than 50%; now they are down to 28% and Toyota is up to #3 in the US displacing Daimler Chrysler. According to the predictions from Sean McAlinden of the Center for Automotive Research, the total sales of the Big Three US Auto manufacturers will be below 50% for the first time ever in 2007. This is a substantial reduction from the 55% in 2006, according to Autodata. This will equate to a loss of an additional 800,000 vehicles for 2007, enough volume to keep four to five plants running. When you compound that by all of the US suppliers for these plants that will have to close, that’s a lot of lost jobs.

Although some of the data below isn’t as current as we would like to see, the charts help illustrate the dire situation we are facing in the US manufacturing sector.

Chart 1: US Automotive Sales Loses Versus Asian Manufactures Gains

Chart 2: Manufacturing Job Losses versus Service Job Gains

We need to choose our attitude to become more responsible. We do have the power to change our circle of influence to drive change. We need to effectively train our fellow workers, whether they are union brethren or not, that it is time to develop a synergistic win-win plan for change. We need to accept our role to create and control our future together not sit back and complain about the state of the deteriorating industry.

I hope I’ve done a sufficient job in stressing the importance and the urgency to utilize the valuable human resources that can help us drive the bus on the journey to change. The ultimate destination of our journey is survival. The passengers on the bus are those that can help us identify and reduce the other Seven Deadly Wastes. We have reviewed the Seven Deadly Wastes and discussed the importance of getting the people involved to help slow down the tide of American manufacturing companies wanting to take advantage of cheaper labor overseas. We need to work together to make sure that our future generations don’t have to accept service jobs because that is all that is left. We can work together to become the most efficient manufacturing machine in the world. Help us utilize our resources to Eliminate the Eighth Deadly Waste!

© Life Cycle Engineering

For More Information

843.744.7110 | info@LCE.com