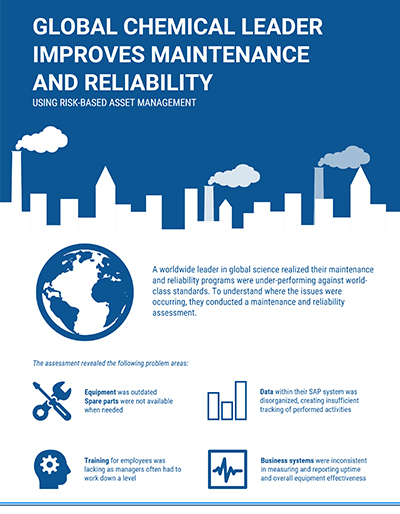

Global Chemical Leader Uses Risk-Based Asset Management to Improve Maintenance and Reliability Performance

A worldwide leader in global science recognized that their maintenance and reliability programs were performing significantly below world-class standards. To understand where the issues were occurring, the company conducted a maintenance and reliability assessment. The findings highlighted the four areas within the business that showed gaps in production efficiency: equipment and spare parts, data, workforce skills and capabilities, and their asset management system.

The assessment provided details of what needed to be overhauled within their maintenance and work management processes. The equipment was outdated, spare parts were not available to the maintenance staff when needed, and the bills of materials (BoMs) were often inaccurate. Along with these issues, the data within their SAP® system was unorganized, resulting in insufficient tracking of performed work. Managers were left working down a level rather than overseeing processes and training staff. Due to the lack of priority, business unit systems were inconsistent in measuring or reporting uptime and overall equipment effectiveness (OEE). This left many units operating below design capacity.

The global science leader knew it needed to completely transform its maintenance and reliability culture to achieve the goal of world-class performance.

Adding value through reliability engineering

To assist with the transformation, the organization enlisted Life Cycle Engineering (LCE), maintenance and reliability industry experts, to create and implement new business processes that would address the failing parts of their work management system.

To address the reliability issues plaguing the businesses equipment and spare parts inventory, LCE instituted a Risk-Based Asset Management (RBAM®) system that connects risk management, standard work and condition-based maintenance to properly apply resources based on process criticality. Utilizing the RBAM strategy, LCE was able to classify and rank equipment based on criticality, which then helped to regain control of the spare parts housing by identifying the critical spares needed to maintain optimal machine performance.

With little to no tracking of preventive maintenance work, the business had little insight into what was causing work order delays. LCE took a holistic approach to address the businesses process, roles and responsibilities and business requirements by optimizing their SAP EAM system. This enabled the staff to understand how the software delivers value to the organization, develop work processes that aligned with industry best-practices, and use the metrics from SAP to produce standard maintenance and reliability reporting.

Through a dedicated workforce effort, LCE’s subject matter experts and coaches worked with the maintenance staff to create focus teams to develop and implement new material management processes and train staff to become reliability engineers.

Reaping the benefits from defined work processes

With a combined effort from both the company’s leaders and workforce, LCE and the global giant experienced positive results including:

· 44% increase in work history

· 38% increase in schedule efficiency

· 26% decrease in PM non-compliance

· Formed a cross-functional team

· WMP gap analysis completed

· Time confirmations running at approximately 80%

· Established eight key reliability engineering processes

o Hierarchy evaluation

o Asset criticality

o Asset control strategy

o Maintenance plan development

o PM Optimization (PMO)

o Critical spare parts analysis

o Loss elimination

o Root Cause Failure Analysis (RCFA)

SAP is the registered trademark of SAP SE in Germany and in several other countries.

RBAM is a registered trademark of Life Cycle Engineering .

Additional Information

For more information about improving operational and financial performance, please email us at info@LCE.com or visit www.LCE.com.

About LCE

Life Cycle Engineering (LCE) (www.LCE.com) provides consulting, engineering, applied technology and education solutions that deliver lasting results for private industry, the Department of Defense and other government organizations. The quality, expertise and dedication of our employees enable Life Cycle Engineering to serve as a trusted resource that helps people and organizations to achieve their full potential. Founded in 1976, LCE is headquartered in Charleston, South Carolina with offices across North America and experience around the globe.

Contact Us

Corporate Headquarters

Life Cycle Engineering

4360 Corporate Road

Charleston, SC 29405-7445

843.744.7110

info@LCE.com