Advanced Predictive MaintenanceSM

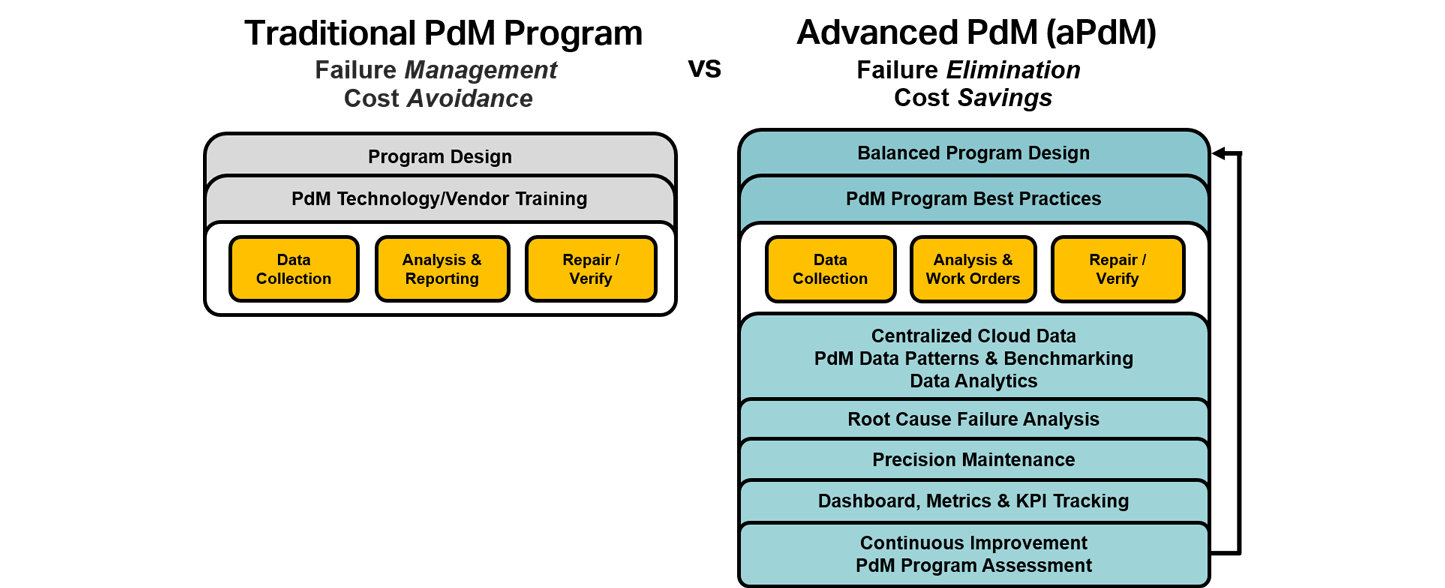

Manufacturers and facility operators struggle to cost-effectively maintain safe and reliable operations for their critical assets. When deployed properly, predictive maintenance (PdM) programs have been successful in identifying impending failures. However, programs often fail to achieve their goals: improved asset reliability and reduced cost.

LCE’s Advanced Predictive Maintenance services help organizations harness the power of PdM technologies to improve the performance of asset-intensive industries and facilities.

Our approach combines a properly managed deployment of predictive technologies with standard processes and statistical analysis to identify and eliminate most reoccurring failures at their root. Eliminating reoccurring failure patterns, essentially preventing failures from occurring, will add true reliability to your facility.

Advanced Predictive Maintenance services will help you:

- Improve overall reliability and increase productivity

- Improve quality and safety

- Reduce emergencies and downtime

- Reduce PM events, troubleshooting and repair costs

Email us to learn more about Advanced Predictive Maintenance

Life Cycle Engineering offers four services to match our clients’ needs and their maintenance and reliability maturity level:

PDM PROGRAM DESIGN

For organizations with no formal PdM program, LCE can design a PdM program that uses appropriate technology to identify failure modes at the lowest cost.

PDM PROGRAM ASSESSMENT

For organizations with an existing PdM program, LCE can review the program’s effectiveness to ensure it is achieving maximum results based on available equipment, resources, budget and tools.

PDM PROGRAM MANAGEMENT

For organizations with a newly designed or existing PdM program, LCE can provide onsite and remote service to manage the program’s effectiveness and ensure it is achieving desired results.

PdM ANALYSIS

For organizations with a newly designed or existing PdM program, LCE can provide PdM data analysis and reporting.