Equipment Maintenance Plans and Job Plans

When equipment maintenance plans are not failure-mode driven, do not include all tasks, and lack skill level and labor hours required, equipment performance suffers and productivity is reduced by doing non-value-added maintenance. As part of a risk-based asset management strategy, effective equipment maintenance plans and associated tasks will help eliminate your current bad actor problems, and improve asset availability while decreasing total cost of ownership.

Life Cycle Engineering (LCE) can develop customized maintenance and job plans for your equipment, taking into consideration OEM manual recommendations, regulatory and industry standards, company policies, appropriate predictive maintenance strategies, historical equipment data, environmental requirements and operating conditions.

Scope of Services:

- Assess and / or develop equipment hierarchy

- Review and collect equipment nameplate and configuration information (where needed)

- Develop equipment maintenance plans (EMPs) for maintainable assets

- Develop maintenance/job plans, in agreed-upon format from finalized EMP

- Recommend any Predictive Maintenance (PdM) job plans where applicable

- Review with client and finalize maintenance /job plans

- Submit finalized maintenance job plans

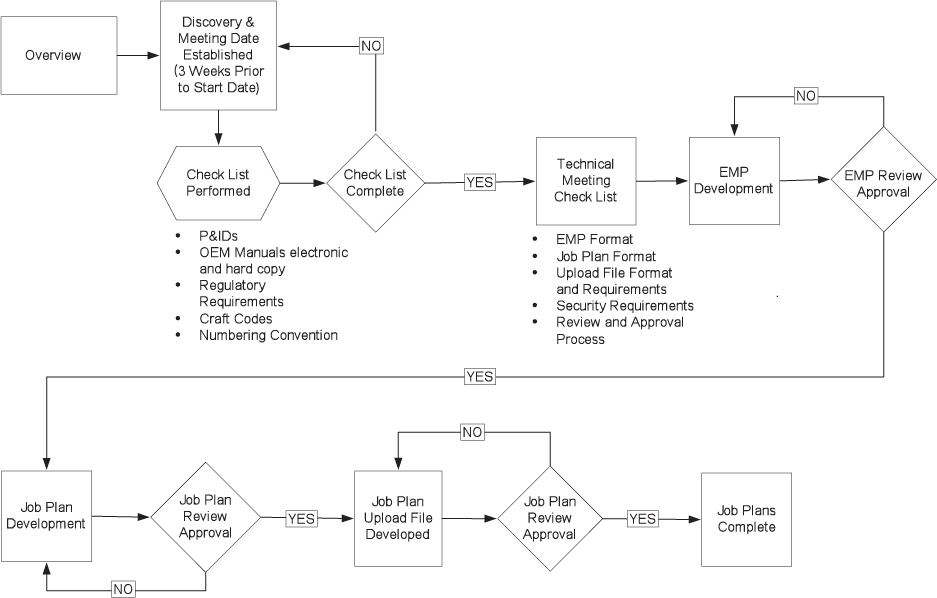

Approach:

Deliverables:

- Equipment maintenance plans (EMPs) for the selected equipment within the project

- Job plans for the PM/PdM tasks included in the EMP

- Uploadable files in MS Excel or MS Word format for migration to your EAM system

Related Links:

Oil Rig Equipment Maintenance Plans and Job-Plans