Checkpoint Process for Operational Readiness

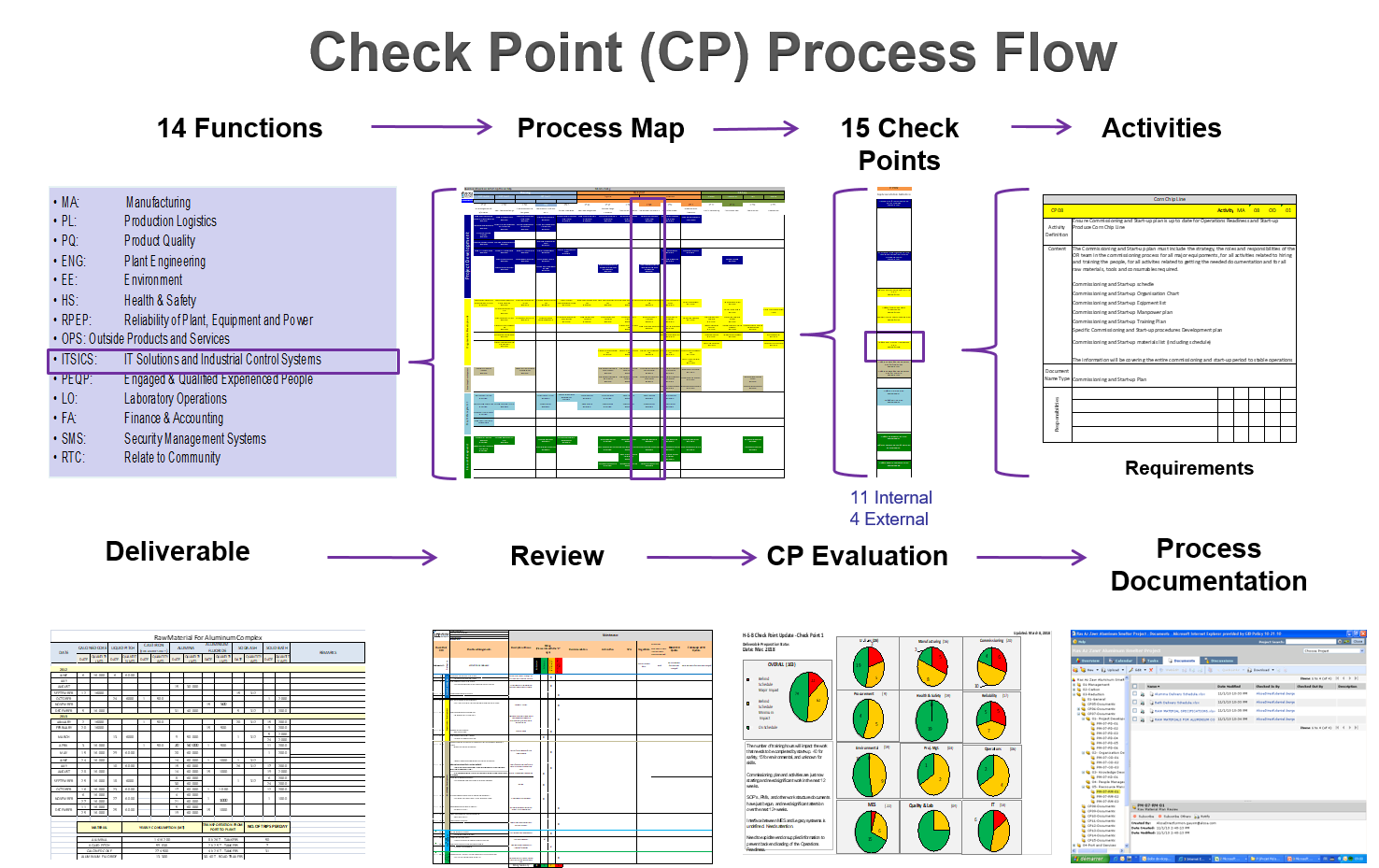

LCE’s Operational Readiness approach uses a checkpoint process that is customizable to the size of the project, and can be staffed with your resources or with LCE’s capable workforce.

To ensure a project is delivered within budget, on schedule, and at desired operational performance from the start, over 1600 activities must be completed. These activities are organized by five areas that are ongoing throughout the delivery of the project:

- Project development

- Organizational development

- Knowledge development

- People management

- Materials management

Each functional area for a new or expanded site (HR, Environmental, Safety, Operations, Maintenance, etc.) has actions that must be completed at the appropriate time to ensure everything is ready for start-up. LCE’s checkpoint process provides a roadmap that validates deliverables at multiple points throughout the project.

Here are a few sample questions you might ask for examples of activities that need to be planned and accomplished at the right time:

- Have Safety, Environmental, and Operating personnel been involved during the design phase?

- Have employees been hired and trained in time to prepare all Operational documentation for start-up?

- Have maintenance employees developed maintenance plans and conducted FMEA (failure mode and effects analysis) to ensure the warehouse stocks are adequate, predictive and preventive maintenance activities can begin immediately following start-up?

- Have procurement personnel established contracts with raw material sources and arranged for onsite deliveries when hot commissioning begins?