Operational Risk Assessment

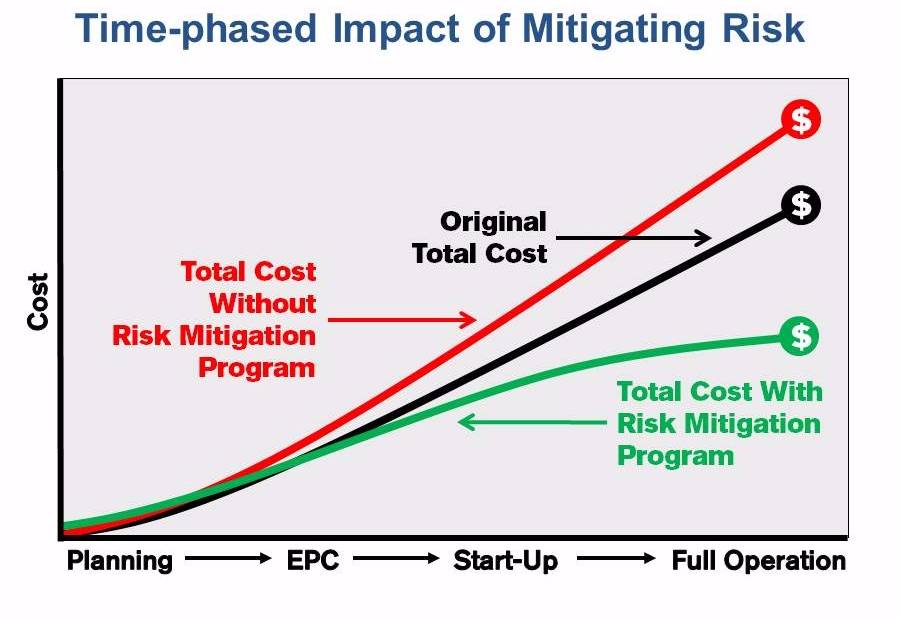

Investing in new assets and facilities poses many operational risks. If you don’t thoroughly assess and minimize risks during the strategy / EPC phases, cost and schedule of facility completion will be impacted and you are likely to experience longer than expected ramp-up time, higher life cycle operating and maintenance costs, excessive downtime, quality issues and potential safety, health and environmental issues.

As part of start-up planning for a new plant or facility, an Operational Risk Assessment will identify risks to the new operation early enough to confirm strategy and put in place timely, cost-effective mitigation measures that will reduce risk in order to boost on-time readiness and lower long-term total cost of ownership.

LCE’s Operational Risk Assessment is a proven process for identifying and evaluating risks to operational readiness for new plants and facilities. LCE’s experts help you identify potential risks, based on LCE’s 40 years of experience working with manufacturing sites and facilities worldwide. We use our experience to help your project team rate the consequence levels and likelihood for each of the categories of risk that are relevant for your operation. We then use a Monte Carlo process to forecast the likelihood of each risk occurrence. This data is used to prioritize the risks and identify strategies, ownership and action plans to eliminate, reduce or transfer the risk. We work closely with you to finalize an action plan to mitigate risks and deliver the expected business results from your new plant or facility start-up.

Your Operational Risk Assessment will produce these deliverables:

• Risk register, organized by category of risk, that describes the risks, potential consequences, likelihood of occurrence, priority of addressing each risk, curves, bar charts, other visual aids to represent level of risk, percent probabilities and comparison of options

• Jointly developed action plan that details options for preventing, reducing or transferring risks, including who is responsible for

each option

• Identified process, schedule and responsibilities for updating the risk register and actions, and communicating progress

Benefits of Conducting a Risk Assessment

Using LCE’s Operational Risk Assessment process enables you to identify, evaluate and mitigate operational risks delivering the following benefits:

• Early identification and mitigation of project risk gives your team the best chance of meeting cost, schedule and quality goals and objectives.

• Successful start-up of your new facility will boost operating performance, improve margins, and position your company to be more competitive in your marketplace.

• Early and thorough consideration and mitigation of all identified potential risks lowers the cost of mitigating risk and reduces your long-term total cost of ownership.

Click here to learn more about an Operational Risk Assessment