Lean Manufacturing

Our Reliability Excellence® business philosophy and methodologies focus on asset dependability, stable business processes and continuously measured results. This disciplined approach to achieving operational stability and continuous improvement is foundational to successful Lean initiatives.

LCE’s Reliability Excellence Model fully incorporates critical Lean aspects in the education, assessment and implementation phases of our proprietary three wave methodology. Our approach to Reliability Excellence is flexible and fully scalable to meet the specific needs of our clients. We work with our clients to develop a master plan that can range from strategic transformation to one that is targeted to resolve specific, performance-limiting tactical issues.

Sustainability of improvements is reinforced through a vigorous change management process that is deployed continuously throughout the implementation process. LCE consultants are certified Prosci Change Management professionals. Our focus on change management enables LCE to create effective and sustainable solutions for our clients.

Lean Implementation Model®

LCE’s approach to Lean is influenced by our 30 years of industry-leading experience providing Reliability Excellence solutions. Reliability Excellence is built upon a solid foundation of standardized processes, repeatable practices and the elimination of variability in all facets of an operation. The Toyota Production System recognizes that Operational stability is foundational to an efficient and effective production system and LCE’s core competency in Reliability Excellence delivers this stability.

Given the scalability and flexibility of our methods LCE can design solutions that meet our clients’ needs. Our “diagnose before prescribing” approach recognizes the need to first agree upon the problem before recommending a solution. Our capabilities range from “dock to dock” holistic implementations to targeted, tactical support designed to solve specific performance-limiting problems.

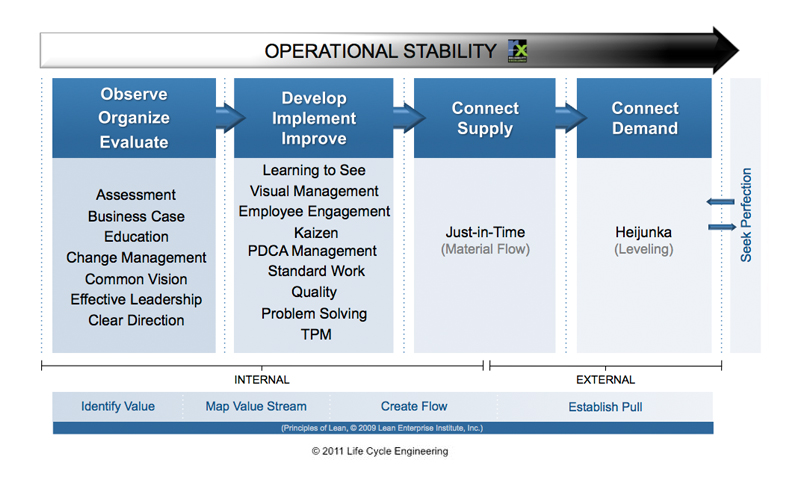

Click Here to Enlarge Lean Implemetation Model

Our holistic Lean Implementation Model progresses through several stages. It begins with developing a business case and is anchored by leadership, education and a robust change management component. The resulting implementation activities deliver operational improvement through the deployment of key concepts supported by selecting the proper Lean tools. The model focuses on developing effective leaders with a clear vision who create, engage and lead a highly motivated and involved workforce through the transformation. Over time, a culture of continuous improvement evolves, producing sustainability.